Metal 3D Printing: Applications & Solutions for Industrial Manufacturing

AddUp, built on the foundation of two industrial manufacturing powerhouses, Michelin and Fives, offers cutting-edge industrial 3D printing solutions. With more than 200 years’ experience in industrial manufacturing, these two companies have overcome the struggles many manufacturers face today. AddUp has leveraged this heritage to build machines to solve manufacturers toughest challenges. Our machines, designed for maximum productivity and throughput, are part of our comprehensive industrial 3D printing solutions for a serial manufacturing environment. Our reliable and repeatable platform coupled with in-process monitoring solutions provide peace of mind for manufacturers across a variety of industries and applications.

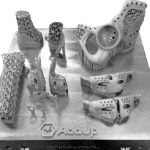

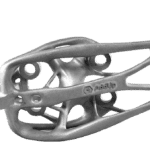

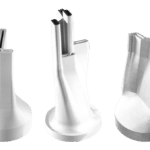

MEDICAL INDUSTRY

The FormUp 350 is currently being used by AddUp customers around the world to create hundreds of certified orthopedic implants each year. For large orthopedic implants, the FormUp 350 answers the medical industry’s need for high productivity, increased operational equipment efficiency (OEE) and lower manufacturing costs. For more detailed spinal or patient specific implants, the FormUp 350 provides increased product differentiation, capable of printing the most detailed features, thanks to our roller recoater technology which allows for fine features and lattice resolution.

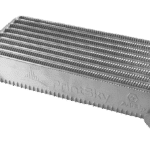

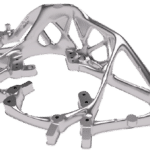

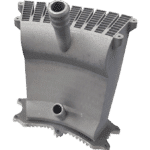

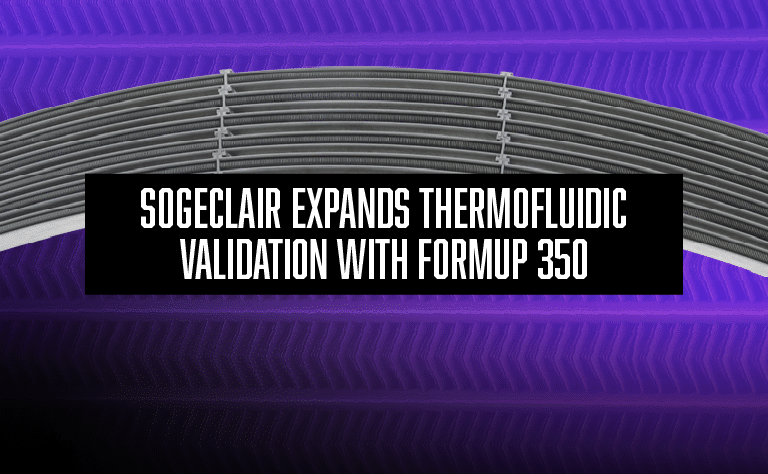

AEROSPACE & DEFENSE INDUSTRY

In the aerospace industry creating parts with more intricate designs and tighter tolerances while optimizing weight savings without compromising structural integrity is paramount. The FormUp 350 offers enormous flexibility in terms of powder use. Depending on the application, market-standard medium powder or fine powder can be utilized. AddUp’s fine powder and roller recoater system allows for parts to be designed with thin walls, fine feature resolution and a superior, smooth surface finish therefore optimizing airflow and maximizing heat transfer efficiency. To support this highly regulated industry, AddUp’s in-process monitoring software provides the confidence in part quality manufacturers expect.

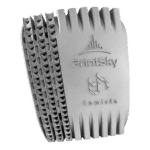

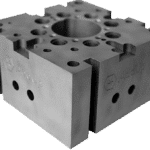

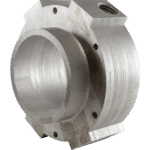

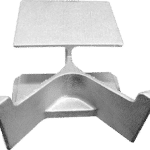

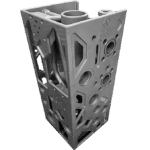

TOOLING, MOLDING & INDUSTRIAL

AM allows for molds to be designed for geometric complexity without limits and can be manufactured on demand, involving fewer parts and significantly less material. The FormUp 350 can be used with standard medium powder or a finer powder PSD in combination with a standard blade or roller recoater system, based on the needs of the application. AddUp technology allows for design complexity while requiring minimum or no supports and achieving a best-in-class surface finish. AddUp’s PBF 3D metal printers take tooling molds and dies to the next level, creating complex molds with internal conformal cooling channels and our DED printers provide solutions for part repair.

OTHER INDUSTRIES

AddUp has more than 20 years experience in additive manufacturing and an industrial pedigree built off of its founding companies Michelin and Fives. Supporting a variety of other industries including automotive, energy and motorsports, AddUp is the experienced partner you can trust to optimize efficiency and maximize performance for your applications using AM.

Industry Certifications

AddUp operates with a strong focus on quality, efficiency and customer-centricity. AddUp’s processes and systems have been reviewed and validated for compliance to applicable ISO standards. We hold multiple certifications around the globe and can help speed up the process of qualifying your part applications based on the needs for your specific industry.

Step Into The Future Of Metal Manufacturing

Today’s metal 3D printers unlock designs impossible with conventional methods, offering unparalleled precision and complexity. Blending groundbreaking innovation and expertise, AddUp is leading the evolution of metal additive manufacturing