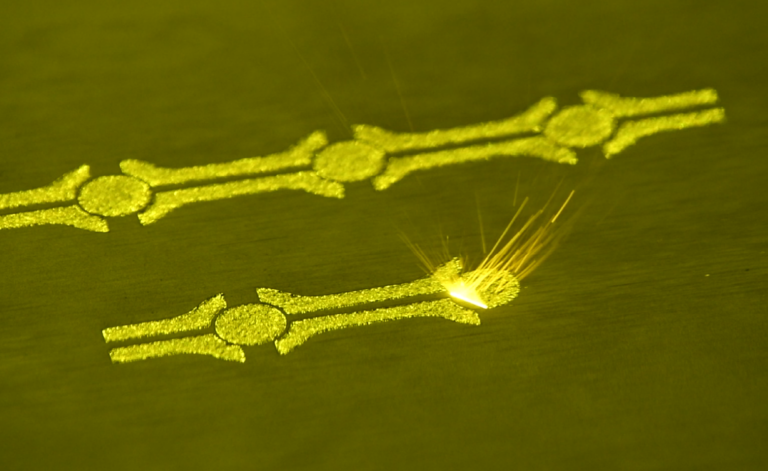

5-in-1 Manifold

When DED technology allows printing parts with complex shapes without additional tooling. A Greek manufacturer Spyros Panopoulos Automotive has asked AddUp to produce 3D-printed parts, including a 5-in-1 manifold. The challenge…

Acetabular Hip Cup Implant

Acetabular Cups plate History Acetabular cups are used during the total hip replacements to sit against the..

ADS Spherical Tank

AddUp 3D printed a spherical tank that can hold the operating pressure of 60 bar for two-phase fluid loop applications using fluids in a supercritical state at maximum non-operating system…

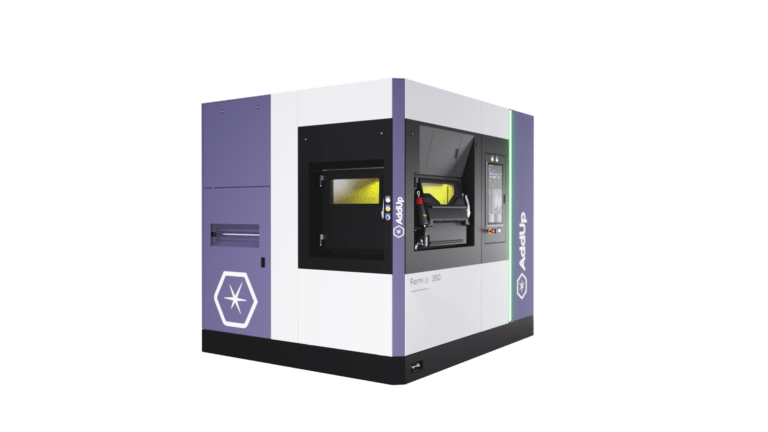

FORMUP 350

The FormUp 350 machine is a solution for metal additive manufacturing PBF. This modular and scalable powder bed fusion machine offers a high level of productivity and allows the manufacture of high-quality parts while ensuring user safety.

FORMUP 350 EVOLUTION

The FormUp 350 Evolution machine is AddUp’s answer to larger PBF parts. The extractible build chamber reduces machine downtime while keeping powder under inert conditions. Based on the FormUp 350, it is 100 % compatible with standard parameters and the powerful AddUp Monitoring solution.

PBF TECHNOLOGY

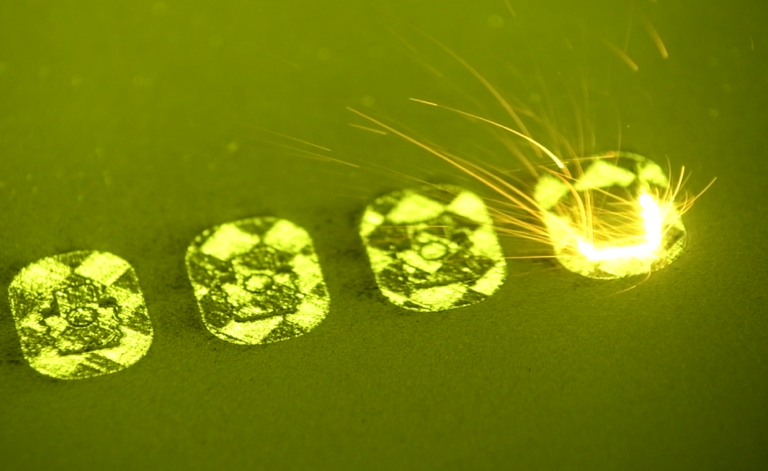

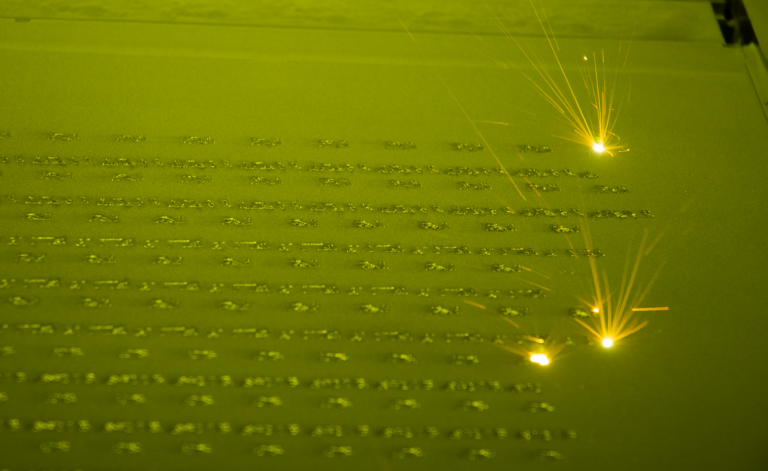

Powder Bed Fusion (PBF) technology is a metal additive manufacturing process that allows the production of high-precision parts with very high mechanical properties.

In a laser PBF machine, parts are made in successive horizontal layers. For each layer, metal powder is spread on a production platform, and a laser melts the areas that need to be solidified.

FormUp 350 machines are safe, efficient and scalable. They integrate more than ten years of experience of AddUp and Michelin in PBF technology.

Reliable. Repeatable. Industrial.

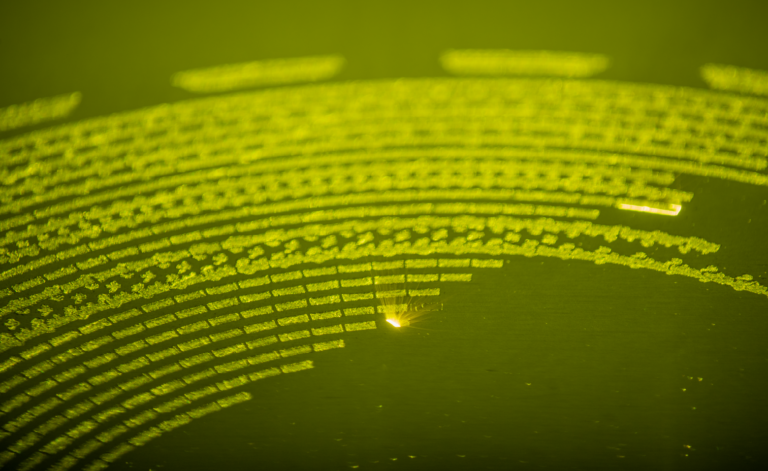

The FormUp range of PBF machines are built to do serial production in a digital manufacturing environment–and to do it well. When you choose an AddUp machine, you gain access to a host of technological advantages working in synergy to produce the very best products–without compromising quality or productivity.

Every component of our FormUp has been designed to deliver parts with best-in-class surface finish, limiting the need for time-consuming post-production stages.

Yet quality does not come at the expense of productivity: each laser (from 1 to 4) can reach the entire platform, offering enormous design flexibility. Intelligent head-load balancing ensures maximum productivity, while limiting thermal stress on parts.

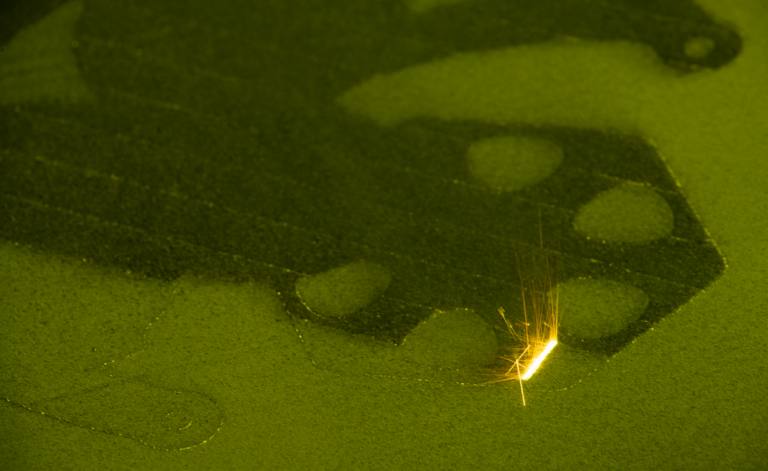

AddUp’s solution differs from competitors by being totally opened in terms of parameters. You can develop specific manufacturing recipe for your project, achieving the best compromise between quality and productivity.

Operator safety is also a major concern for AddUp. That’s why our FormUp features a totally inert, closed-loop powder management system, which limits user exposure to powder. This system also ensures continuous supply to FormUp, eliminating the need for reloading during production.

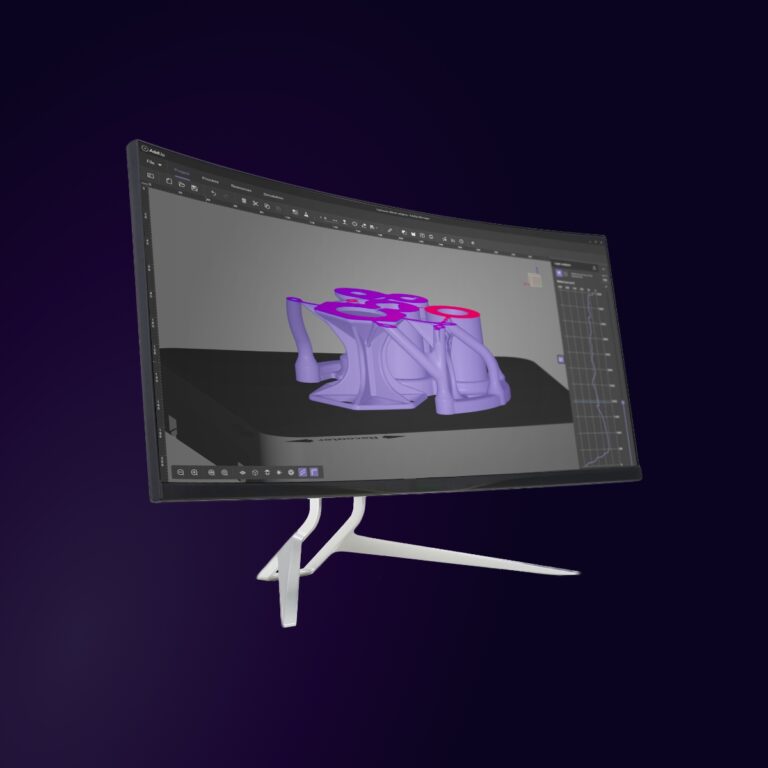

SMART SOFTWARE

Software is at the heart of additive manufacturing. It is the key to performance, flexibility and precision.

From part preparation to simulation, monitoring and production, every link of the AddUp digital chain offers a high level of performance with complete ease of use.

Enter The smart Era In Metal Manufacturing

Today’s metal 3D printers make parts that can’t be made by traditional manufacturing methods. Metal Additive Manufacturing is the way of the future, and AddUp is leading the way.