Rooted in Industry, Pioneering the Future of Additive Manufacturing

Reliable. Repeatable. Industrial.

AddUp has more than 20 years experience in Additive Manufacturing. Our machines are built to do serial production in a digital manufacturing environment–and to do it well.

THINK SMART. MANUFACTURE DIFFERENT.

From the industrial roots of our founding partner companies, Michelin and Fives, to technology built for the future, AddUp machines provide innovative solutions to manufacturers’ challenges. Pressed to find cheaper, smarter, and faster ways to meet market demands, manufacturers are looking for a reliable partner to guide them along their additive manufacturing journey. They want a guide who, beyond machines, provides a new vision of manufacturing for the future. AddUp is that guide.

In applying our industrial experience in building complex parts with our reliable and repeatable additive manufacturing machines, we help customers manufacture in a safer, cleaner, and more efficient way through digital manufacturing.

Proud Heritage

We were built upon the pedigree of industry pioneers Michelin and Fives. With more than 20 years of AM experience, we know how to use it, qualify it, and scale it–making it a reliable and repeatable solution for your business.

Proven Track Record

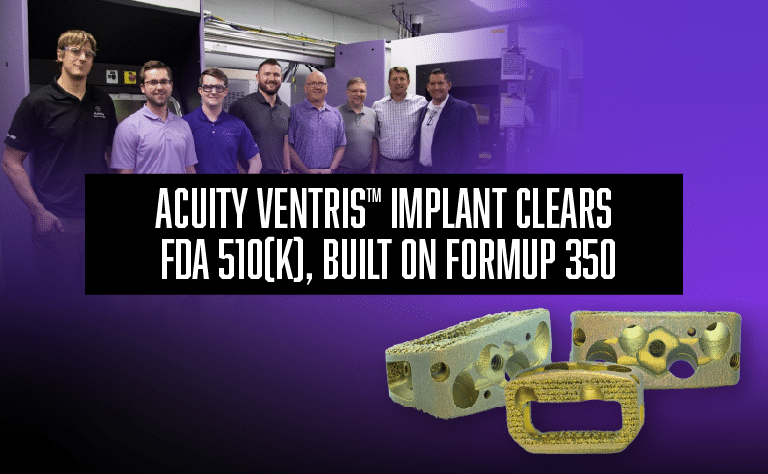

Our machines are repeatable and reliable. Every day parts are produced on AddUp machines. You can find them on satellites, aircrafts, trains, automobiles and even in the human body.

The Gold Standard of Service

Your satisfaction is our #1 goal. That’s why we are focused to ensure you receive top-quality, white glove service across all your interactions with AddUp.

Safety as Our Priority

We take care of what matters. We have the most advanced systems to ensure both our team and your teams’ safety.

Time and Cost Savings

With our machines’ ability to build parts with best-in-class surface finish “as printed”, our customers save time and money on post processing and finishing.

Maximum Performance

Our machines are designed to meet an OEE level demanded for serial production.

Smart Machines

With more than 20 years experience in Additive Manufacturing, our machines have been designed to master detail and optimize productivity.

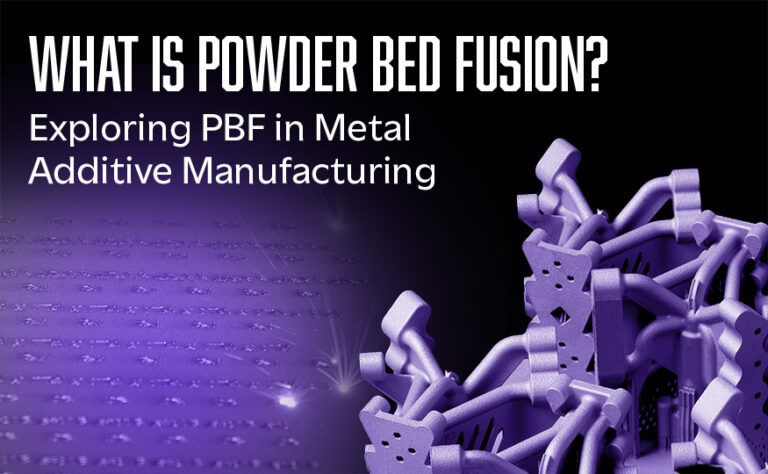

Best-in-class surface finish–that’s what you can expect with an AddUp machine. Using our Powder Bed Fusion (PBF) machines, we achieve these results thanks to our proprietary fine powder and roller recoater technology giving us excellent surface finishes and allowing us to create parts with very few support structures. Using our Directed Energy Deposition (DED) machines, we achieve a more consistent powder delivery and less overspray thanks to our dual-flow coaxial nozzle, providing an unrivaled smooth surface finish.

AddUp’s closed-loop powder handling system allows customers to safely use all types of metal powders, even the most reactive ones, such as titanium and aluminum alloys in fine powders. Operators can work without touching powder, and waste is safely disposed of without exposing machine users to smoke or melting residues.

Our software is built for the future and to run additive manufacturing at an industrial scale. Whether it is manufacturing preparation, simulation of constraints, machine control, production report, or traceability, AddUp offers an industrial software solution to showcase the full potential of its machines in PBF and DED technologies. Powerful and fully integrated, these intelligent digital solutions ensure real-time validation and quality control of printed parts during production.

Customer Benefits

We understand what’s important to our customers. That’s why our machines were built to be more efficient, smarter and faster to meet market demands and solve manufacturers toughest challenges.

Leveraging the advanced capabilities of our machines, which excel in producing parts with a best-in-class surface finish “as printed,” our clients benefit from substantial time and cost savings by minimizing the need for extensive post-processing and finishing.

Rooted in manufacturing, we have designed our machines to protect users. With our Autonomous Powder Module, for example, users can run their machines without touching any dangerous materials or exposing reactive metal powders to possible ignitions or explosions. Users can also avoid exposure to carcinogens through an automatic passivation filter system that keeps them from breathing in harmful fumes.

AddUp’s robust software suite provides confidence in part quality, limiting the need for rigorous testing, and allowing access to data from both hundreds of machine data at a glance (macro) as well as at the microscopic level, giving detailed views into machines and processes.

A Partner for your AM Journey

Our Customer JourneyWe have the knowledge and experience to help you at any stage of your project. At your service from the very first contact, we help you define your needs, identify the right technology and materials, guide you through the qualification process and support you as production ramps up. We are with you through every stage of your AM journey.

Identify the Applications

Optimize Your Parts and Develop the Process

Qualify the Process

Implement Serial Production

“AddUp has demonstrated a set of capabilities that enable us to address unique design and application challenges faced by our growing base of aerospace, space, and defense customers.”

Greg Morris

"AddUp group has enabled our complex designs to become a reality using metal Additive Manufacturing, a state-of-the-art process. This will change the way we create and customize a motorcycle. Our creativity is now limitless, which was impossible with traditional metal manufacturing processes."

Simon Dabadie

"The AddUp team has proven to live within their proclaimed values… delivering a beneficial experience, being a trusted partner, and encouraging innovation. As I navigate through projects, I have been impressed with the level of attentiveness and service they exhibit. Each interaction is laced with education, professionalism, and care."

Shannon VanDeren

"The FormUp350 is one of the only machines on the market that can run both the typical LPBF powder cut and a much finer cut of powder. This gives us flexibility to meet certain challenging applications we may come across in the future."

Rachel Levine

"AM is in a state of exponential growth with the biggest challenges in adoption being qualification and certification. NSL is focused on partnering with companies who are passionate about driving innovation for metal 3D printing.

Over my past three years working with AddUp they have demonstrated a commitment to industrializing additive technology. The evolution of the FormUp 350 has made significant advancements in its full-field, 4-laser system and its monitoring suite which helps to accelerate the qualification process. Advancements like this prove AddUp to be a major player in the growing AM industry."

Ed Herderick

"Too often partnerships are constrained by mistrust and an unwillingness to share information, but the AddUp team has really committed to the partnership with open minds and a shared goal to drive towards large scale part production. Not to mention the FormUp opens the door to productivity improvements with its quad laser setup, open parameters, and long-life filter."

Rachel Levine

"With AddUp as a partner, we are trying to push metal 3D printing technology to its limits in terms of part sizes and associated material health. The quality of AddUp’s printing systems as well as the expertise and motivation of the teams have allowed us to move forward in an open and efficient way."

Francois Billig

"We chose AddUp as our machinery partner for our recent project due to their High-Quality Products and Innovative Technology. AddUp's commitment to research and development leads to cutting-edge solutions, like the Modulo 400 system, which offers versatility and high-quality results. This aligns perfectly with our vision at the Application Center for Additive Manufacturing at Research Institutes of Sweden AB, where we aim to lead in applied research and collaborate on new materials and solutions for the market."

Seyed Hosseini

“As an early adopter of AddUp machines, I really appreciate capabilities and proactive team spirit, to deliverer parts in a serial mode.”

Aurelien Fussel

"The only French manufacturer of powder bed laser fusion machines (LPB-F) offering rare expertise both on the process and its applications with a machine capable of safely producing high quality parts in a repeatable and reliable way."

Jean-Christophe Augé

“AddUp’s proprietary technology is a game changer for the medical AM space. Their quad-laser system can print our parts up to 4x faster, and look much better than other platforms we were previously printing on. Our partnership with AddUp has been instrumental in our success and future growth.”

David Nutter

“The FormUp 350 is a dream come true for us. It’s on the cutting edge from both a software and hardware perspective. The large build volume and quad laser system allow us to get production jobs done faster than the competition, while the roller recoater lets us push the design envelope to the next level.”

Noah Smith

The Gold Standard of Service

AddUp experts are ready to support you throughout your AM journey. Even after your machine is up and running, our team is committed to providing a gold standard of service. We pride ourselves on our industry leading response times and strive to exceed customer expectations by delivering exceptional experiences. You can count on AddUp to be the partner you rely on to consistently deliver high-quality service.

Certified Facilities Worldwide

AddUp operates with a strong focus on quality, efficiency and customer-centricity. AddUp’s processes and systems have been reviewed and validated for compliance to applicable ISO standards. We hold multiple certifications around the globe and can help speed up the process of qualifying your part applications based on the needs for your specific industry.

A Global Presence to Support Our Customers Locally

AddUp is headquartered in Cébazat, France, with a North American subsidiary based out of Cincinnati, Ohio, and a German subsidiary based in Aachen, Germany. In addition to machine design and manufacturing, the AddUp group also offers part production, POC production, metal AM consulting services, AM training, and design for AM, making AddUp your one-stop for metal AM, wherever you are located.

Get Started with AddUp

Realize the potential digital manufacturing has to offer. Get started with AddUp and learn how AM delivers innovative solutions to solve manufacturers toughest challenges.