PRODUCTIVITY AND QUALITY

IN A SINGLE MACHINE

Industry leading surface finish, with better meltpool control, and productivity built for industry, that’s what you get when you buy an AddUp DED machine. Discover our Modulo 400 for more advanced DED applications.

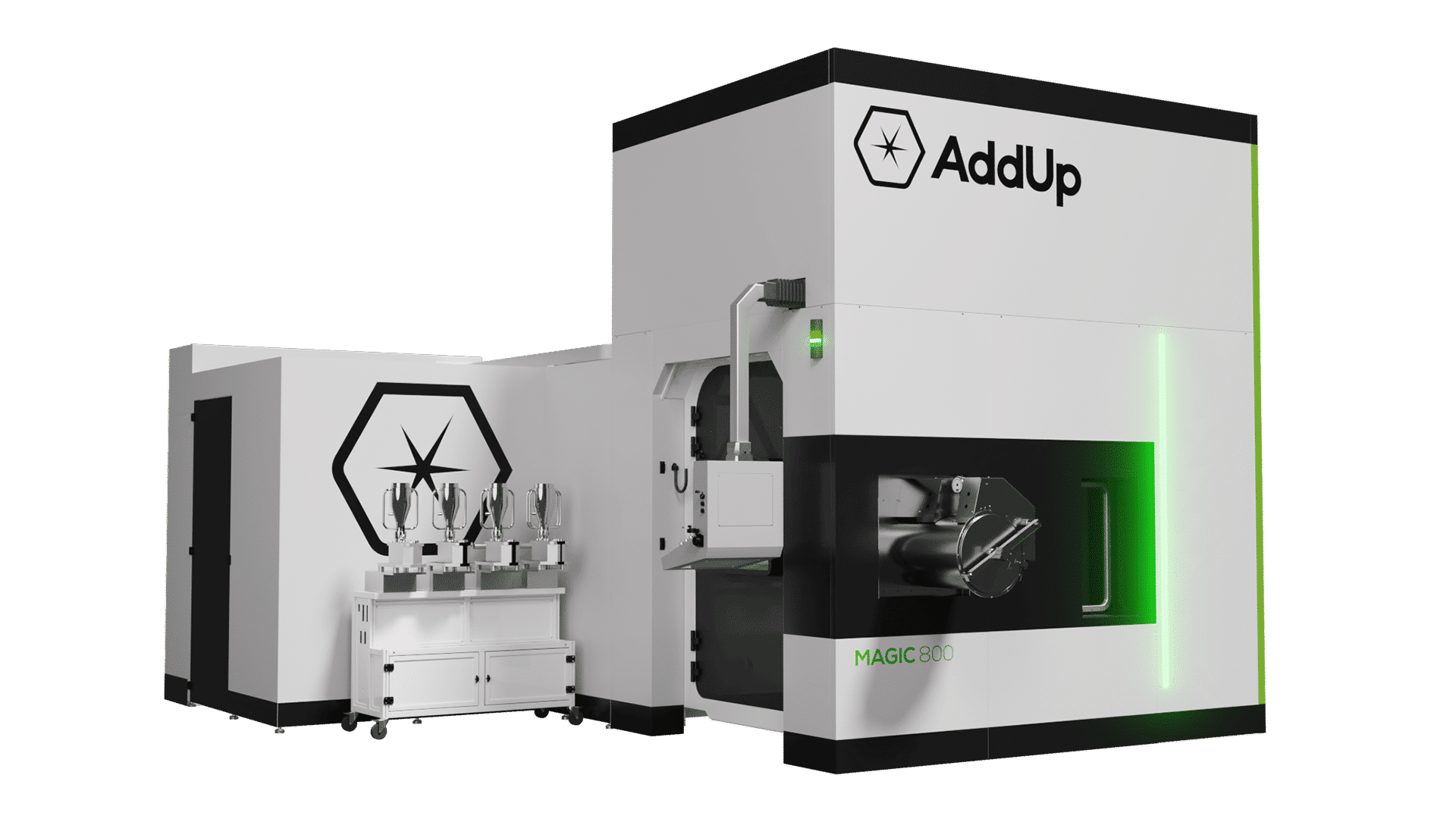

The Magic 800 machine is a DED additive manufacturing machine that can be equipped with two nozzles of different sizes and power. Opt for the 24Vx nozzle to make the massive sections of your parts, then automatically change during production to the 10Vx nozzle to make parts that require precision.

- The 10Vx deposition nozzle (optional) can deposit weld beads 0.8 to 1.2 mm wide, with an accuracy of 0.1 mm.

- The 24Vx deposition nozzle (standard) can deposit weld beads 1.8 to 2.2 mm wide, with an accuracy of 0.2 mm.

- Nozzle change takes a few seconds, without interrupting production.

Many devices available as standard or optional on the Magic 800 make this machine a concentrate of technology. To name only a few: vibration powder dispenser for stability and reliability in the powder supply of the deposition nozzle, and automatic deposition nozzle change system, including a probe for significant productivity gains and adaptive repair applications.

Customer Successes

Read about the success our customers have had with DED technology on a variety of applications

5-in-1 Manifold

When DED technology allows printing parts with complex shapes without additional tooling. A Greek manufacturer Spyros Panopoulos Automotive has asked AddUp to produce 3D-printed parts, including a 5-in-1 manifold. The challenge…

Automotive

Multi-Metal, Multi-Technology Piston Head

This case study presents the development of multi-metal, multi-technology piston head The goal was to improve wear resistance and performance, as well as internal cooling channels.

Aerospace

Isogrid Case Study

Combining Traditional Manufacturing with Additive – Adding Features with Directed Energy Deposition

CERTIFICATIONS

In AddUp’s trusted hands, your manufacturing will have a gold standard of safety. AddUp has an ASTM certification and best in class safety, reducing exposure to powder thanks to our APM. AddUp will also be by your side with industry leading response times and support for accelerated qualification leveraging our certifications along with our experience from Michelin and Fives.

Technical Specifications

The Magic 800 DED is the largest 5-axis CNC, blown powder DED machine in AddUp’s fleet. With its 2-kW laser, two exchangeable heads (optional), and an impressive build volume of 1800 mm x 1000 mm x 1000 mm.

MAGIC 800 (standard)

| MACHINE SIZE | |

|---|---|

| Dimensions | L 5,9 x W 7,2 x H 4,1 m |

| Total weight | ~ 20 tons (without powder) |

| DED NOZZLE | |

|---|---|

| Type | 24Vx |

| Laser | Ytterbium fiber - 2000 W |

| Optical fiber diameter | Ø 600μm |

| Cord width | 1,8 to 2,2 mm |

| Average deposition rate | 90 - 130 cm3/h |

| POWDER | |

|---|---|

| Number of feeders | 2 (2 available as option F) |

| Powder feeder technology | Vibration |

| Capacity | 2,5 L (approx. 13 kg of standard steel) |

| Powder flowrate | 1 - 30 g/min |

| MOVEMENTS | |

|---|---|

| Number of axis | 5 (simultaneously and continuously) |

| Linear axis stroke | X= 1000 mm, Y= 1800 mm, Z= 1000 mm |

| Rotary axis stroke | A = +/-110°, C = +/-360° |

| TABLE | |

|---|---|

| Table diameter | Ø 700 mm |

| Building volume | 1800 x 1000 x 1000 mm |

| Maximal load | 5 axis: 500 kg (part holder included) 3 axis: 800 kg (part holder included) |

| CNC | |

|---|---|

| Controller | Siemens SINUMRIK ONE |

| Compatability | G-code |

| SECURITY | |

|---|---|

| Laser | Door with laser protection glass |

| Exhaust filtration | 3 levels: pre-filter, HEPA, chemical filter |

| CONTROLLED ATMOSPHERE |

|

|---|---|

| Gas type | Argon |

Materials Available

The Magic 800 was designed to handle a variety of metallic powders. AddUp offers ready-to-use parameters for each of those, but customers can also define or fine-tune those depending on their needs.

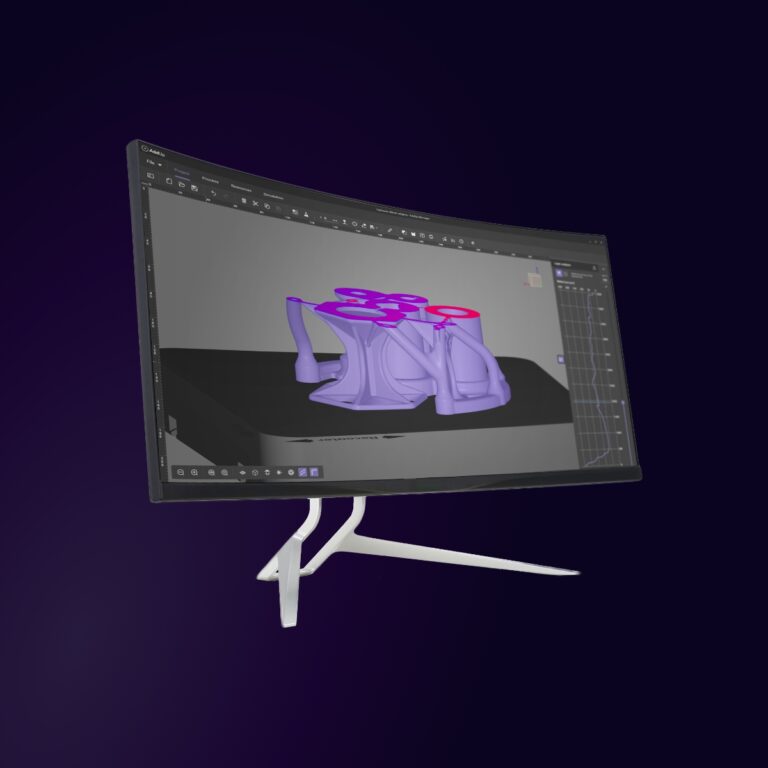

LEARN MORE ABOUT MATERIALS FOR THE MAGIC800SMART SOFTWARE

All Magic 800 DED machines are compatible with the AddUp Dashboards, a real-time tracking solution fully customizable solution which provides hands-on machine conditions. Create your own visualization sets, define variables you want to see and set your conditional alerts. Read and write administration can also be set to adjust different needs for different profiles.

BEYOND THE MACHINE

AddUp experts are ready to support you throughout your AM journey. Even after your machine is up and running, our team is committed to providing a gold standard of service. We pride ourselves on our industry leading response times and strive to exceed customer expectations by delivering exceptional experiences. You can count on AddUp to be the partner you rely on to consistently deliver high-quality service.

Enter the Smart Era in Metal Manufacturing

Today’s metal 3D printers make parts that can’t be made by traditional manufacturing methods. Metal Additive Manufacturing is the way of the future and AddUp is leading the way.