The FormUp 350 Powder Bed Fusion (PBF) machine revolutionizes the manufacturing of large spinal fusion devices, offering increased efficiency, precision, and cost-effectiveness.

Introduction

Spinal fusion devices play a crucial role in the medical field, providing essential support and stability in spinal surgeries. Traditionally, large spinal fusion devices were produced using small format Powder Bed Fusion (PBF) machines or machined out of poly bar stock. While these methods were effective, they presented several challenges, including high costs and lengthy production times. However, the advent of advanced manufacturing technologies, such as the FormUp 350 PBF machine, has revolutionized the production process, offering enhanced efficiency, precision, and improved patient outcomes.

Traditional Manufacturing Methods: PBF and PEEK

The conventional manufacturing process of large spinal fusion devices relied on PBF or machining out of PEEK bar stock. These methods, while effective, were not without their drawbacks. The production process was slow and costly, leading to increased prices for the finished implant. Additionally, when produced using PEEK, these types of implants lacked ideal Osseo integrative features, which are crucial for the success of the implant. Moreover, the unstable material supply chain for PEEK presented further challenges in the manufacturing process.

The Advent of Additive Manufacturing

The introduction of additive manufacturing marked a significant shift in the production of large spinal fusion devices. However, the manufacturing of these devices on smaller platforms with 1-2 lasers increased the cost of the finished implant. These implants were tall in Z, leading to increased build times that were further increased with a small number of lasers. Furthermore, the use of a scraper/brush recoating process and the need for wire electrical discharge machining (EDM) to remove the LLIFs from the build plate added to the overall time and cost of production.

The FormUp 350: A Leap Forward in Spinal Fusion Device Manufacturing

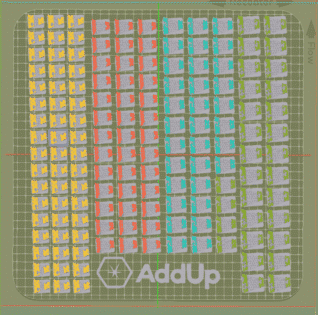

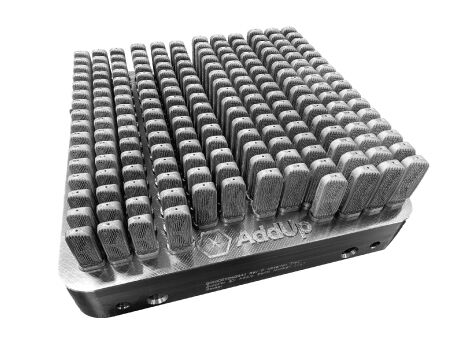

The FormUp 350 PBF machine has emerged as a superior alternative to smaller platforms with 1-2 lasers. Thanks to a 350 millimeter squared build plate, the FormUp 350 can hold 1.5 times the amount of large spinal implants compared to smaller platforms. The use of 4 lasers allows for 152 large spinal implants to be printed in just 32 hours, significantly reducing production time and increasing output.

The FormUp 350 utilizes a powder roller technology which allows for geometric complexity using minimal supports and results in optimal surface finish. This technology enables the realization of intently designed complex structures and surface roughness that contributes to better patient outcomes. There is no longer a need for a plasma porous spray or sheet-based trabecular surface, and the surface roughness is not a byproduct of the process. This helps to decrease the manufacturing processes required to complete a finished product, reducing costs along all parts of the supply chain and supporting more efficient patient outcomes.

The Impact of the FormUp 350 on the Medical Device Industry

The adoption of the FormUp 350 in the manufacturing of large spinal fusion devices has far-reaching implications for the medical device industry. By reducing lead times and increasing precision, the FormUp 350 allows manufacturers to respond more quickly to market demands and produce higher quality products. Moreover, the ability to print complex structures and achieve optimal surface roughness improves the performance of the implants, leading to better patient outcomes. This is a significant advancement, as it not only enhances the quality of life for patients but also reduces the need for revision surgeries, leading to cost savings for both patients and healthcare providers.

Results

Large spinal implants produced using small build capacity, low number of lasers, and traditional recoating systems cost more than when produced using the FormUp 350.

The FormUp 350 machine is ideal for medical applications because it provides an improved and cost-effective process to mass-manufacture highly complex and/or customized medical parts.

Parts built per laser on the FormUp 350:

- 2 Laser – 76

- 4 Laser – 38

Time to build on the FormUp 350:

- 2 laser – 52.95

- 4 laser – 32.35

Annual throughput on the FormUp 350:

- running 1 shift per day for 52 weeks per year

- 1 – 1.5 from laser off to laser on (build flip)