Aerospace

Cassegrain Antenna

Ready-for-Flight Antenna in Powder Bed Fusion Thales Alenia Space is a french aerospace manufacturer that has played a significant role in space exploration for more than 40 years. As new […]

Automotive

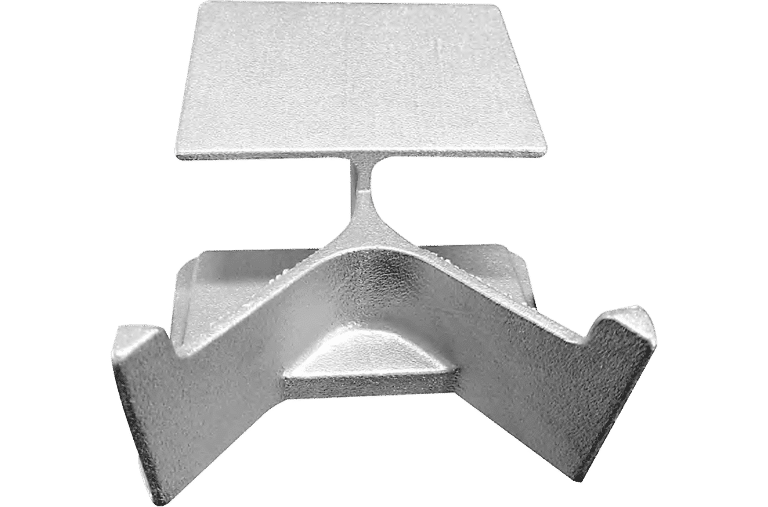

Michelin Tires Sipes

Discover how Michelin produces over one million tire sipes a year for their production molds using metal 3D printing When Michelin found that the metal AM machines on the market did not meet their high-quality…

Aerospace

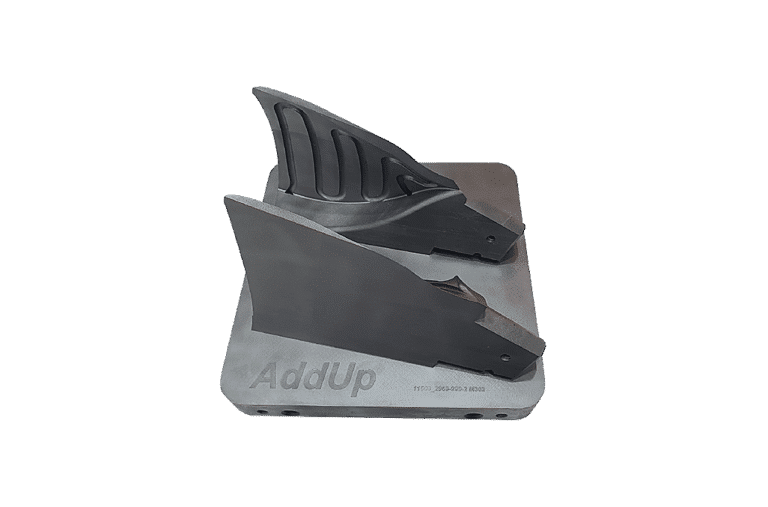

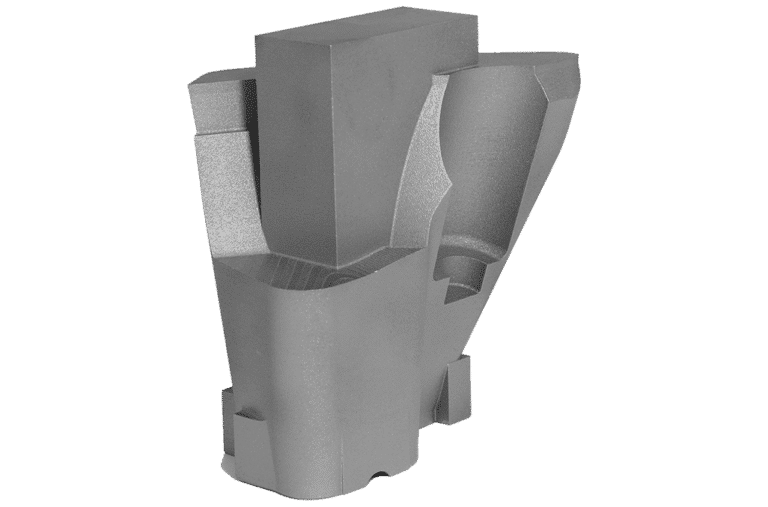

Rocket Nozzle

AddUp optimized the design of a rocket nozzle to improve the performance of a micro-launch vehicle. Metal additive manufacturing can lead to fuel and production savings in aerospace. In this case…

Medical

Spine Implants

This case study focuses on spine implants and the challenges faced in their manufacturing process today. Additive Manufacturing (AM) offers benefits such as lattice design and surface roughness, leading to…

Aerospace

Isogrid Case Study

Combining Traditional Manufacturing with Additive – Adding Features with Directed Energy Deposition

Tooling

Gira Socket Injection Mold Case Study

An improvement in temperature control are guaranteed by employing intricate complex conformal cooling channels using the design freedom of AM.

Automotive

Multi-Metal, Multi-Technology Piston Head

This case study presents the development of multi-metal, multi-technology piston head The goal was to improve wear resistance and performance, as well as internal cooling channels.

Aerospace

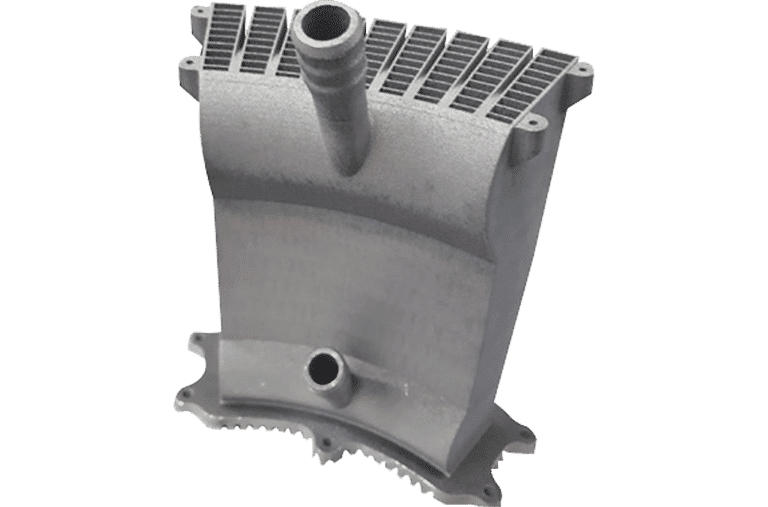

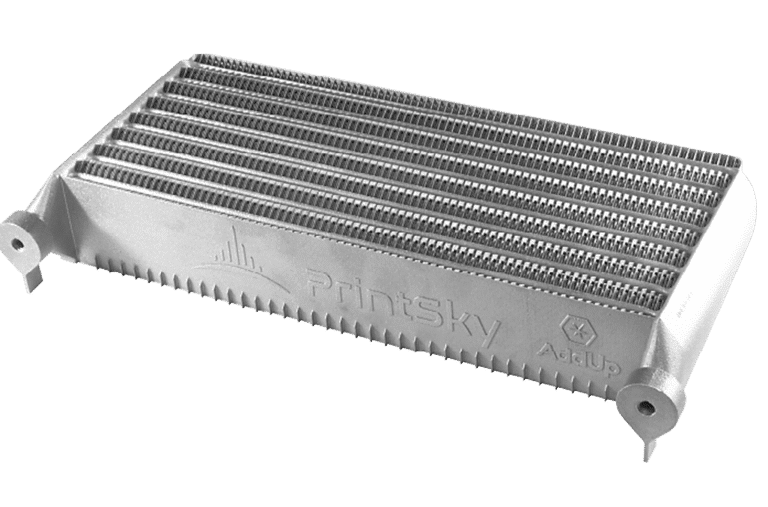

FormUp Heat Exchanger

This case study presents the development of an optimized heat exchanger for the Form Up® 350 machine,. The goal was to improve heat dissipation and adapt the dimensions for easy installation.

Aerospace

Heat Exchanger Aluminum AlSi7Mg

The goal is to demonstrate an interest in the PBF technology to create heat exchangers with improved compactness, good thermal performance, and metal 3D printed in one go. Answering the aerospace…

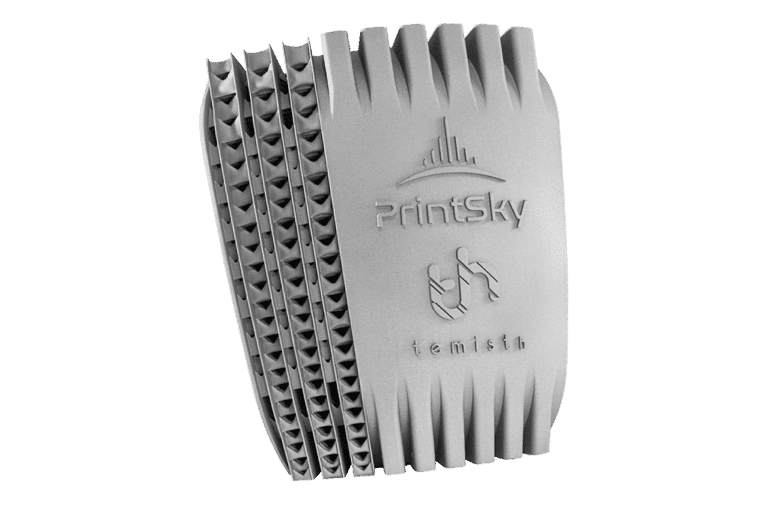

Aerospace

Aerospace Support Part

See how AddUp and PrintSky develop a good rigidity/mass balance with a high technical and economic value for an aeronautical part. The CEA (French Alternative Energies and Atomic Energy Commission) has joined forces…

Tooling

Orano Manifold Spare Part

The goal of the project is to verify the technical and economic feasibility of additive manufacturing of complex geometric replacement parts for equipment that is no longer manufactured. The project aims…

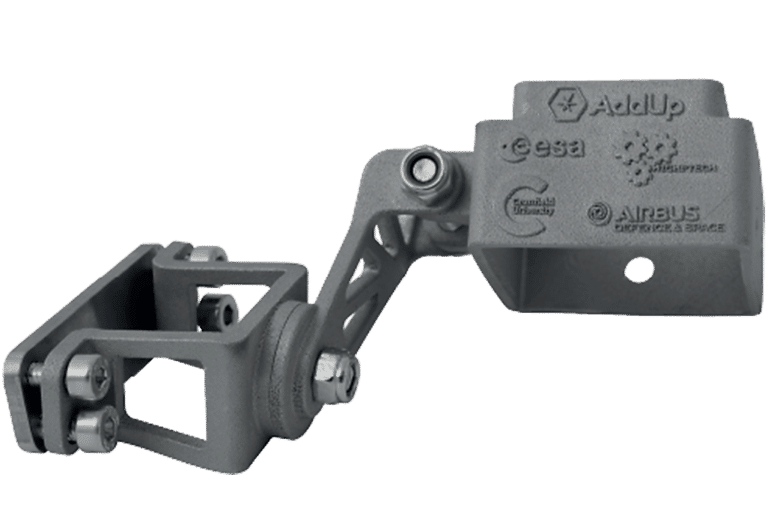

Aerospace

Space Camera Support

An additively manufactured camera support, designed to withstand acceleration and vibration during launch to space and to hold a camera and its lens in position during the production phases of…

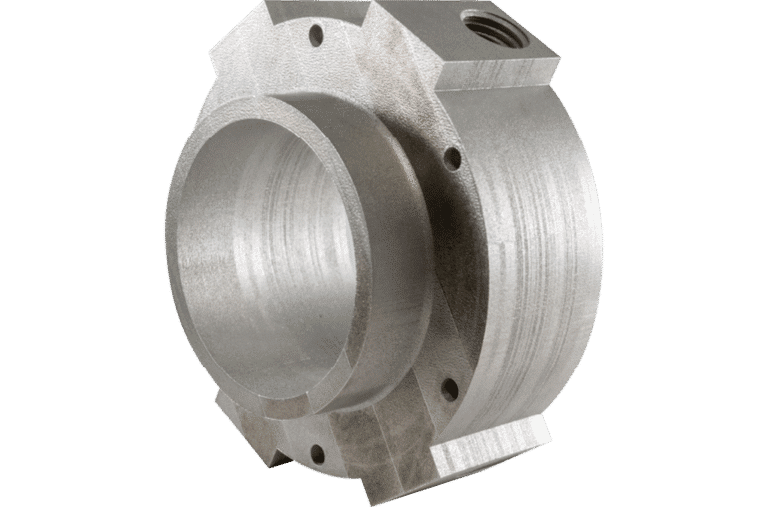

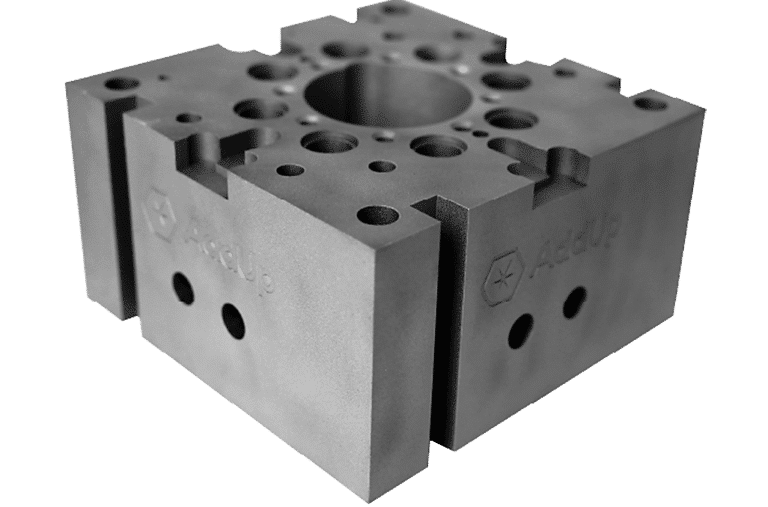

Tooling

Hydraulic Block

Hydraulic blocks are present in most machines and devices, throughout a variety of industries. In the case of this hydraulic block, the entire part is 3D printed in a single…

Aerospace

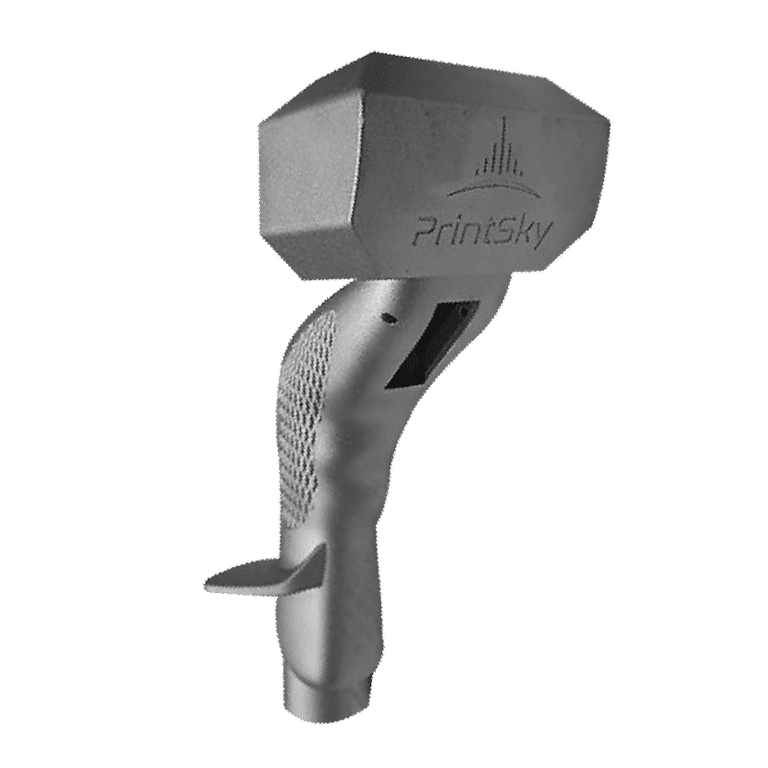

Joystick

The freedom of design linked to metal 3D printing allows the production of customized handles, of different dimensions, without tooling, thus limiting the costs and manufacturing lead times of the…

Defense

French Navy Scraper

How reverse engineering process and metal 3D printing allow to produce an identical and durable strategic part for a boat. As this part was no longer in stock, nor produced by…

Tooling

Grinding System Coolant Nozzle

A one-piece optimized coolant nozzle that delivers coolant flow into precise locations. The nozzle was officially installed grinding machine, optimizing its performance. History Fives is an international industrial engineering group with over 200+…

Energy

Schneider Inductor

See how this 3D printed inductor has met all quality specifications, and its industrial performance has surpassed initial expectations. An induction heating coil is a production tool that allows performing a…

Tooling

Siebenwurst Injection Mold

This case study explores the benefits of using 3D printed injection molds with optimized cooling channels. The project between Siebenwurst and AddUp aimed to improve productivity and quality in the…

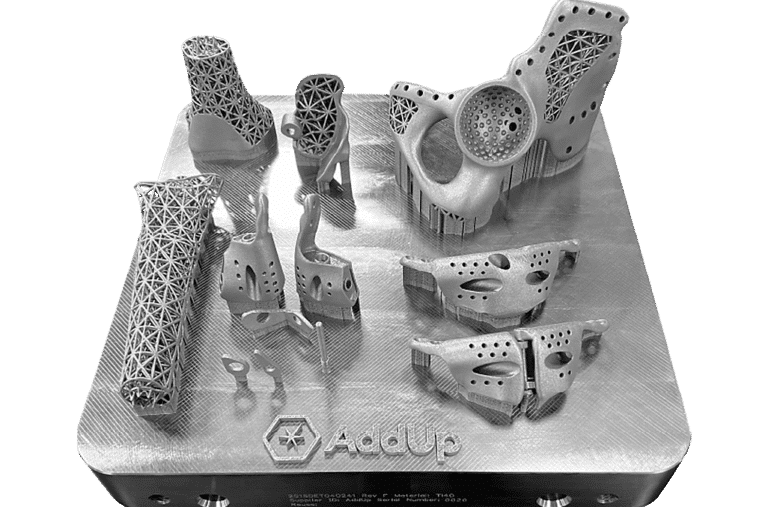

Medical

Tibia Tray

This case study focuses on tibia trays in orthopedic manufacturing and the challenges faced in producing highly complex and customized implants. Additive Manufacturing (AM) using biocompatible materials like titanium offers…

Medical

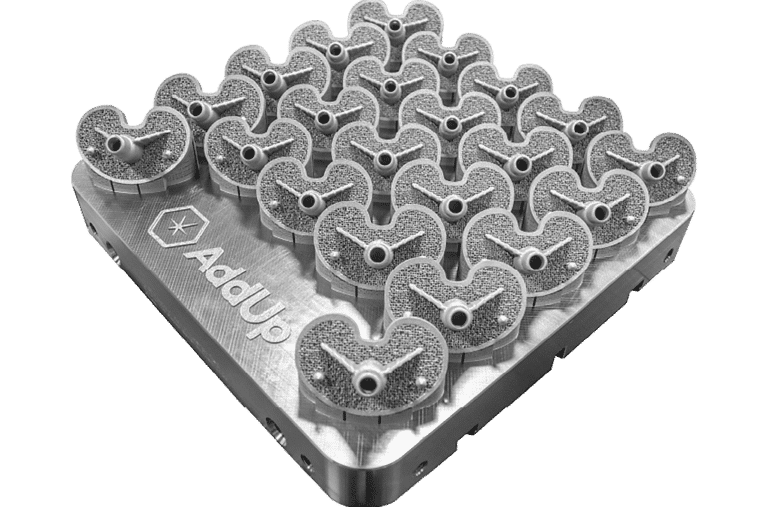

Acetabular Hip Cup Implant

Acetabular Cups plate History Acetabular cups are used during the total hip replacements to sit against the..

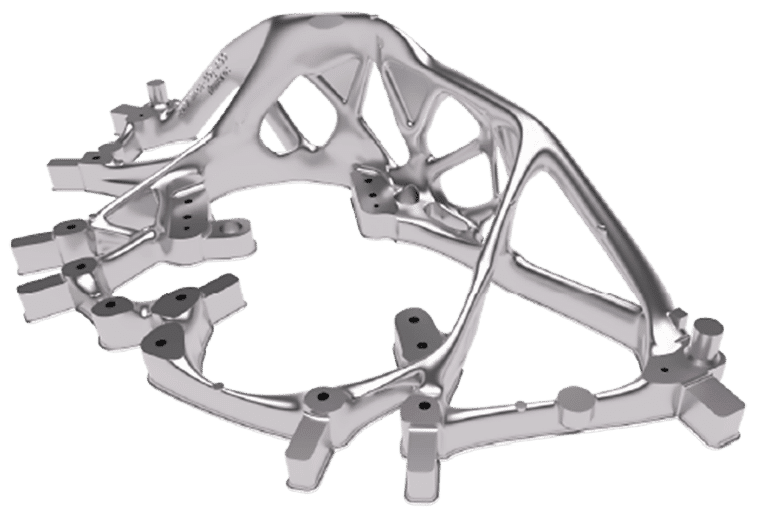

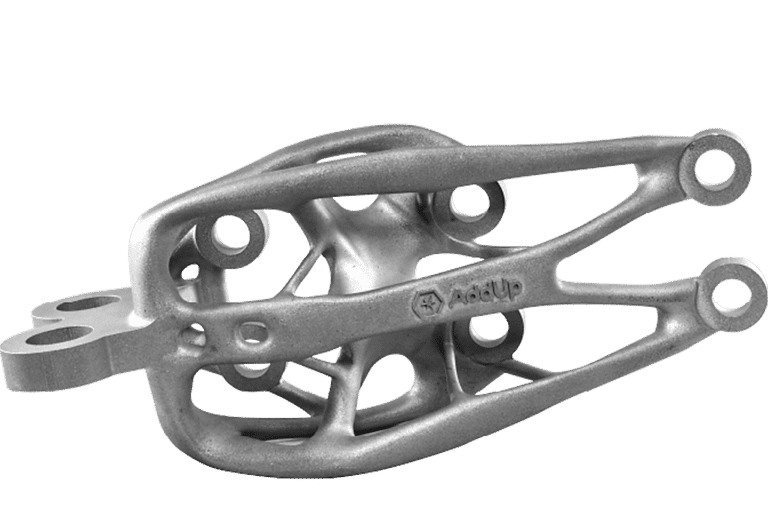

Aerospace

Aircraft Floor Bracket

This proof of concept demonstrated by Add Up showcases the value of using Additive Manufacturing (AM) for aeronautics by applying topological optimization to an aircraft floor bracket. History An aircraft floor bracket…

Medical

Patient Specific Implants

This case study highlights the advantages of using additive manufacturing (AM) for Patient Specific Implants (PSI) in the orthopedic industry. By shifting from traditional manufacturing to AM, orthopedic OEMs can…

Tooling

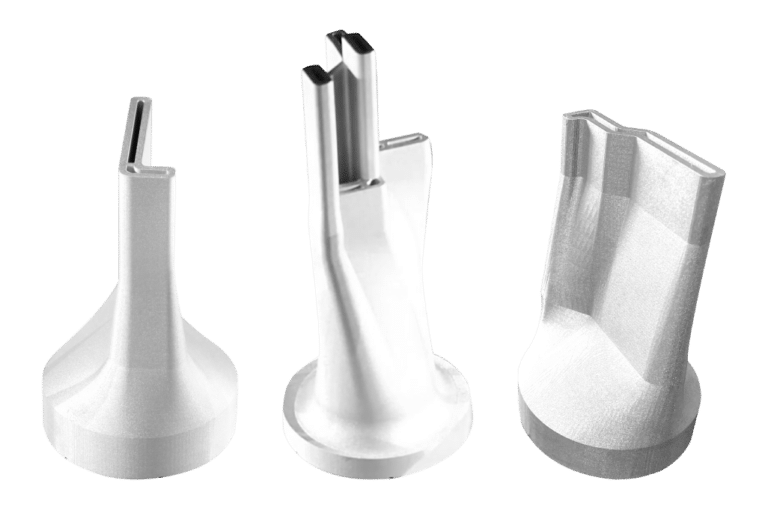

Extrusion Die

This study explores the use of additive manufacturing, specifically Powder Bed Fusion (PBF), to create extrusion dies with improved performance and cooling capabilities. History Extrusion is a popular manufacturing method for parts…

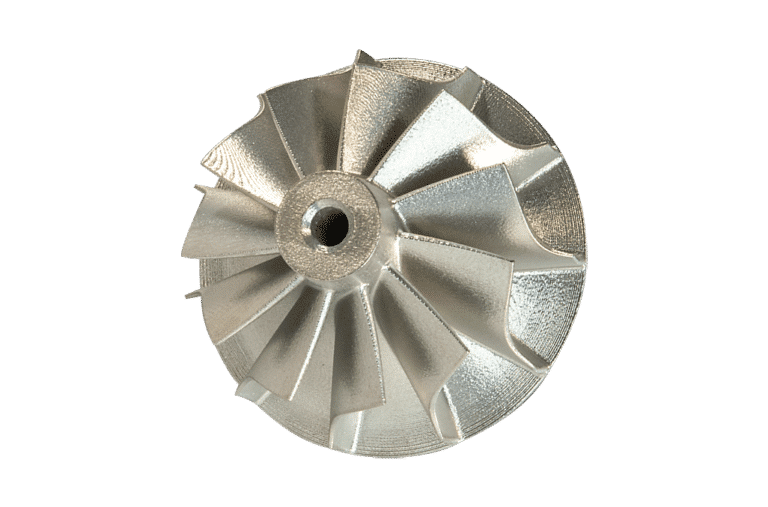

Automotive

Impeller Wheel

This case study explores the feasibility of using additive manufacturing, specifically the Form Up 350 PBF machine, to produce over 100,000 Impeller wheels annually for Ford, replacing traditional machining techniques. History Ford…

Aerospace

HEWAM Heat Exchanger (Inconel)

Addup 3D printed a double-curved heat exchanger, suitable for curved surfaces with very successful thermal performance and produced in one go. For thermal equipment, additive manufacturing has a huge advantage. It…

Tooling

Injection Mold

See how to improve the cooling of the inserts on a mold using additive technology while increasing the mold’s performance and decreasing the cycle time. Short injection times are crucial for…

Automotive

5-in-1 Manifold

When DED technology allows printing parts with complex shapes without additional tooling. A Greek manufacturer Spyros Panopoulos Automotive has asked AddUp to produce 3D-printed parts, including a 5-in-1 manifold. The challenge…

Aerospace

Heat Exchanger

Read the case study to understand how to obtain a viable heat exchanger with good thermal and mechanical properties in a reduced time frame. AddUp and PrintSky join forces to increase…

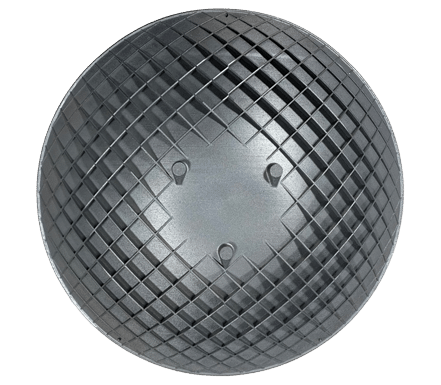

Aerospace

ADS Spherical Tank

AddUp 3D printed a spherical tank that can hold the operating pressure of 60 bar for two-phase fluid loop applications using fluids in a supercritical state at maximum non-operating system…

Tooling

Siebenwurst Door Handle Injection Mold

Improving Injection Mold Hotspots for Optimal Cooling Capabilities Through Additive Manufacturing

GET THE LATEST INSIGHTS DELIVERED TO YOUR INBOX

Step Into The Future of Metal Manufacturing

Today’s metal 3D printers unlock designs impossible with conventional methods, offering unparalleled precision and complexity. Blending groundbreaking innovation and expertise, AddUp is leading the evolution of metal additive manufacturing