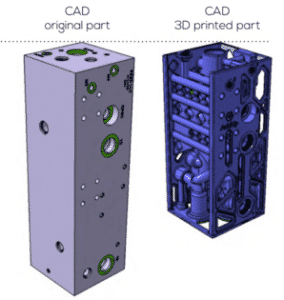

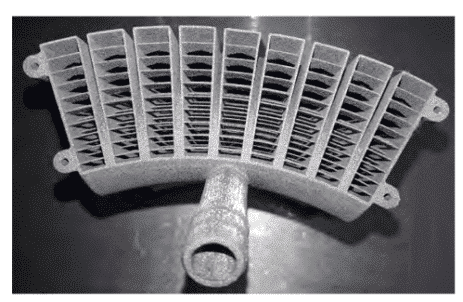

The goal is to demonstrate an interest in the PBF technology to create heat exchangers with improved compactness, good thermal performance, and metal 3D printed in one go.

Answering the aerospace industry’s issues on thermal gear through the Powder Bed Fusion technology (PBF process) is what Temisth and PrintSky – the AddUp SOGECLAIRE Joint-Venture – propose under a partnership with the European Space Agency. In this study, the aim was to meet the needs of the space industry. The part was produced in aluminum on a FormUp 350 machine provided by AddUp.

OBJECTIVE

Develop a heat exchanger using the full potential of PBF process

RESULTS

- Good thermal performance for a smaller volume compared to “conventional“ exchangers

- Printed all at once

DIMENSIONS

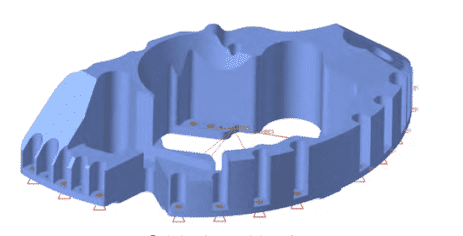

- 116x116x60 mm Mass: 244 g Heat exchanging power: 2,3 kW (simulated result)

Context

PrintSky is a joint venture between AddUp group, an expert in metal additive manufacturing, and SOGECLAIR, specializing in the integration of high-value-added solutions in the fields of aeronautics, space, civilian and military transport. Temisth is specialized in the development of custom thermal solutions customized using additive manufacturing. The goal for PrintSky and Temisth was to demonstrate their interest in the PBF (Powder bed fusion – laser) technology to create heat exchangers with improved compactness.

Used Means

Printsky has developed its own methodology for dimensioning heat exchangers to the given characteristics. In this example, the aim was to meet the needs of the space industry. The part was produced in aluminum on a FormUp 350 machine provided by AddUp.

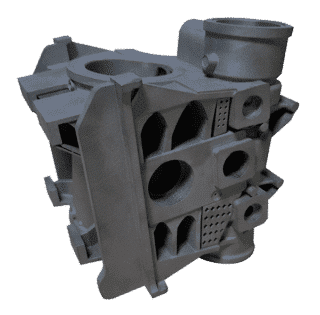

Advantages of Metal 3D Printing

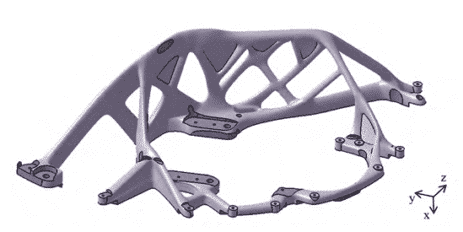

Metal additive manufacturing is relevant for thermal equipment. It allows for the creation of channels with complex shapes, thus improving thermal performance while reducing the volume. This heat exchanger has thin walls (250 μm) and double curvature channels that are impossible to produce by conventional techniques. The tests carried out on a test bench allowed us to validate the leak tightness of the part, as well as its performance, very high considering the compactness of the exchanger. PrintSky has obtained a partnership agreement with the ESA (European Space Agency) for the development of this aluminum part.

The AddUp Advantage

Metal powder in fine particle size, used here on the FormUp machine, allows surface conditions adapted to heat exchanges.