Utilizing metal 3D printing for part repair, manufacturers can overcome supply chain challenges, reduce production costs, and ensure rapid availability of complex parts.

Any operations manager knows that when a part breaks, the immediate consequence can be a stop in production, loss of business, or even a customer. It is imperative to keep facilities operational in a complicated environment, whether it be in the oil & gas, energy, or defense sectors.

Repairing damaged equipment, producing spare parts on-demand…These promises of metal 3D printing have been talked about for decades, but so far have been used minimally in the scope of the industrial world. Recently real industrial applications of additive manufacturing repair are beginning to emerge, helped by the improved performance and robustness of Laser Powder Bed Fusion (L-PBF) and Directed Energy Deposition (DED) machines.

How can additive manufacturing optimize your supply chain?

At the beginning of 2021, the French group Orano, a major player in nuclear fuel cycle products and services, published the results of a project conducted in partnership with AddUp. The aim was to analyze the feasibility and profitability of producing spare parts using metal 3D printing.

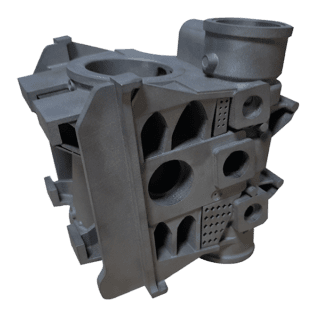

The study covers several complex parts. One of these is a steam distribution block, which has a particularly long lead time and needs to have sufficient spare parts in stock.

The parts were produced on an AddUp FormUp 350, a laser powder bed fusion machine. The Orano experts carried out various tests on these blocks, including strength tests, to validate that the printed parts had the same mechanical characteristics as the original parts. These tests were conclusive, making it possible to remove the common misconception that parts produced by metal 3D printing are less efficient than machined parts. Above all, the manufacturer made its calculations: for this type of part with complex geometries, the production of 16 parts in additive manufacturing is equivalent to the price of 3 machined parts.

In order to cope with the obsolescence of certain equipment, we called on AddUp to 3D print our metal spare parts. The result is unexpected: the same design with complex geometries, the same mechanical characteristics, and above all, a 50% reduction in production costs compared to machining. Thanks to metal additive manufacturing, Orano now has an additional, agile, reliable, and economical supply chain for spare parts.

Ana-Paula Serond, Ph.D., Innovation Manager – Direction Innovation, Orano

The issues Orano faced are recurrent in the industry and led to the launch of this project. In assembly plants or process industries, supply times for complex parts are generally counted in weeks and can lead to considerable operating losses when complete plants are shut down. In addition, manufacturers operate their machines over several decades. It is not uncommon for part drawings to become unavailable, or suppliers of the equipment no longer exist.

More and more projects in defense and space

The need for rapid availability of spare parts is also found in other industries, such as oil platform operators. Here, the issues are less about the complexity of the parts and more about the ability to supply them quickly in isolated areas. Another example is the defense sector, where armed forces around the world are looking at the possibility of having mobile additive manufacturing units capable of monitoring operations and producing spare parts on-demand as close to the battlefield as possible. The space sector has been evaluating the possibility of having metal additive manufacturing onboard space missions for a number of years. Several projects are on the verge of completion, including one currently being developed in partnership with AddUp.

Metal 3D printing can demonstrate real potential, whether it’s about:

- limiting costs related to the storage of parts,

- reducing manufacturing times,

- decreasing transport times,

- or building more agile and environmentally friendly supply chains for spare parts.

The French Environment and Energy Management Agency (ADEME) published a study in 2017 encouraging all French 3D printing players to develop parts repair services.

Repairing parts with DED

All of the projects mentioned so far involve the manufacture of parts on demand. However, we can’t deal with the subject of metal additive manufacturing applied to maintenance activities without mentioning Directed Energy Deposition (DED) technology, which allows applications for the repair of existing parts.

Repair already accounts for 15% of DED technology applications and allows metal to be deposited on existing parts. The repair of worn parts by adding material is not new. For several decades, manufacturers have already been using welding robots, but they often tend to damage the parts. Thanks to DED technology, the repair of parts is becoming much more precise.

The use of a laser beam allows the creation of very thin metal beads around 1 mm wide, as opposed to several millimeters for traditional welding techniques that use electric arcs to melt the metal.

The beads are also thinner than in welding, allowing:

- Deposition of the right thickness of material,

- Reduced machining times (to bring the part back to its original dimensions),

- Less deformed parts.

The heat-affected zone, which is the area of the part that undergoes a rise in temperature, is less important with DED than with traditional welding, which limits the risk of degrading the mechanical characteristics of the parts.

Like PBF technology, DED technology no longer needs to demonstrate its ability to produce parts with very high mechanical characteristics. As proof, AddUp counts among its clients an aeronautical industrialist, one of the most demanding sectors in terms of metallurgical quality of parts, who has qualified a repair application on one of the most critical parts of all: an aircraft engine rotor. The industry was able to prove to the certification authorities that the rotor, instead of being replaced after 10,000 flight hours, could be recharged by DED and remanufactured up to four times, thus extending its life to 50,000 hours.

Conclusion

In conclusion, regardless of the technology used, L-PBF or DED, recent applications in the fields of maintenance, repair, and spare parts production show that metal additive manufacturing has gone beyond the study stage to become an industrial reality.

DOWNLOAD CASE STUDY