Diverse Applications of Additive Manufacturing Across Industries

Given the opportunity to efficiently produce high-quality, complex parts for sophisticated uses. The diverse applications of additive manufacturing are well-suited for a range of industries. If less waste, more performance, or serial production is needed, Additive Manufacturing can help.

Industries

Automotive

Additive Manufacturing is used in the automotive industry for the creation of complex geometries and intricate designs to improve the performance and efficiency of parts. In this industry, rapid prototyping is also an advantage offered by AM, enabling shorter product development cycles. Utilizing AM for tooling, molds and dies for the automotive industry can also lead to reduced cost and material savings. There are also challenges for the automotive industry such as production speed and scalability for high-volume production. AddUp’s FormUp 350 has been designed for serial production in an industrial environment. It is a manufacturing workhorse, designed for dependability and built to maximize production with minimal downtime for maintenance or turnover between different builds.

Motorsport

Motorsport vehicles need to be as lightweight as possible to achieve high speeds and better performance. Additive Manufacturing allows for the creation of highly complex and lightweight parts which would be impossible to achieve through traditionally manufacturing methods. AddUp has more than 10 years experience providing high level motorsport engineering solutions. Our customers include some of the biggest motorsport teams and cars with AddUp parts are frequently represented in internationally famous championships.

Energy

In the energy sector, components like turbine blades, heat exchangers, and fuel nozzles require complex geometries to enhance efficiency and performance. One of the diverse applications of additive manufacturing is the production of intricate internal structures and designs that traditional manufacturing methods cannot achieve, leading to better energy conversion and utilization. AddUp’s AM machines offer companies the ability to produce higher-quality parts without sacrificing design freedom. AddUp’s expertise across both Powder Bed Fusion (PBF) and Directed Energy Deposition (DED) provide our customers the unique ability to optimize applications using both technologies.

Luxury

The luxury industry is exploring the diverse applications of additive manufacturing for its unique capabilities to create intricate, customizable, and high-quality products. Luxury brands have the ability to create customized and complex designs tailored to individual customer preferences. Within watchmaking for example, AM can be used to manufacture parts with extremely fine details, complex shapes, and specific material properties, contributing to the precision and aesthetics of luxury timepieces. AM can also achieve surface textures that contribute to the aesthetics and value of luxury items. AddUp’s FormUp 350 machine is poised to create luxury parts with fine detail thanks to the use of a finer powder and roller recoater system.

Metal Additive Manufacturing Applications

The use cases for Additive Manufacturing are varied across different industries. See how AddUp customers have had success using our PBF and DED technologies.

ZAHORANSKY Autoinjector Housing

Autoinjector housings are produced in very high volumes and must meet demanding requirements for dimensional accuracy, cleanliness, and consistency. Rising global demand for MED-PEN injection devices, especially those used for […]

Tooling and Molding

Harting Han-Eco

High-volume plastic components place strict demands on cooling performance, tool stability, and cycle time efficiency. For the Han-Eco plug, one of HARTING’s most widely used industrial connectors, thick wall sections […]

Aerospace

Cassegrain Antenna

Ready-for-Flight Antenna in Powder Bed Fusion Thales Alenia Space is a french aerospace manufacturer that has played a significant role in space exploration for more than 40 years. As new […]

Michelin Tires Sipes

Discover how Michelin produces over one million tire sipes a year for their production molds using metal 3D printing When Michelin found that the metal AM machines on the market did not meet their high-quality…

Rocket Nozzle

AddUp optimized the design of a rocket nozzle to improve the performance of a micro-launch vehicle. Metal additive manufacturing can lead to fuel and production savings in aerospace. In this case…

Spine Implants

This case study focuses on spine implants and the challenges faced in their manufacturing process today. Additive Manufacturing (AM) offers benefits such as lattice design and surface roughness, leading to…

Aerospace

Isogrid Case Study

Combining Traditional Manufacturing with Additive – Adding Features with Directed Energy Deposition

Tooling

Gira Socket Injection Mold Case Study

An improvement in temperature control are guaranteed by employing intricate complex conformal cooling channels using the design freedom of AM.

“AddUp group has enabled our complex designs to become a reality using metal Additive Manufacturing, a state-of-the-art process. This will change the way we create and customize a motorcycle. Our creativity is now limitless, which was impossible with traditional metal manufacturing processes.”

Simon Dabadie

SMART MACHINES

With more than 20 years experience in Additive Manufacturing, our machines have been designed to master detail and optimize productivity.

AddUp Materials

Materials are an integral part of Additive Manufacturing. The choice of materials directly impacts the design possibilities and each material has a wide range of properties such as strength, flexibility and heat resistance to meet specific requirements and applications. Learn about AddUp’s suite of materials which have been validated on our PBF and DED machines.

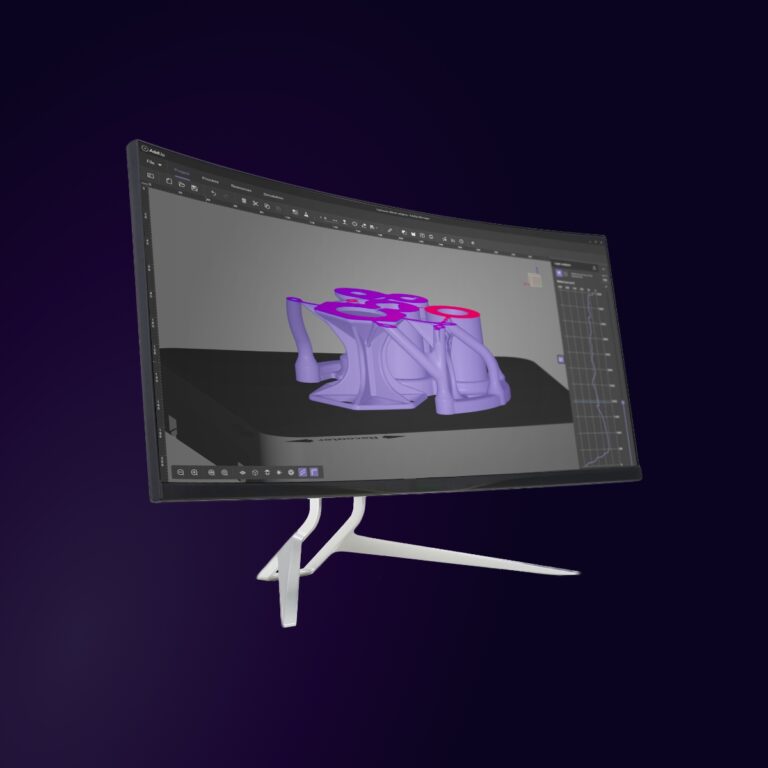

MaterialsSOFTWARE SUITE

AddUp’s suite of digital solutions focuses on quality assurance and cost of control reduction. From part preparation to simulation, monitoring and production, every link of the AddUp digital chain offers a high level of performance with complete ease of use.

Get Started with AddUp

Realize the potential digital manufacturing has to offer. Get started with AddUp and learn how AM delivers innovative solutions to solve manufacturers toughest challenges.