Think Smart MANUFACTURE DIFFERENT

AddUp is industrializing Metal Additive Manufacturing. We know how to use it, qualify it, and scale it–making it a reliable and repeatable solution for your business.

Ask an addup ExpertMetal Additive Manufacturing Machines For Every Need

With more than 20 years experience in metal Additive Manufacturing, our machines have been designed to master detail and optimize productivity. Reliable. Repeatable. Industrial. AddUp machines are built to do serial production in a digital manufacturing environment, providing innovative solutions to solve manufacturers toughest challenges.

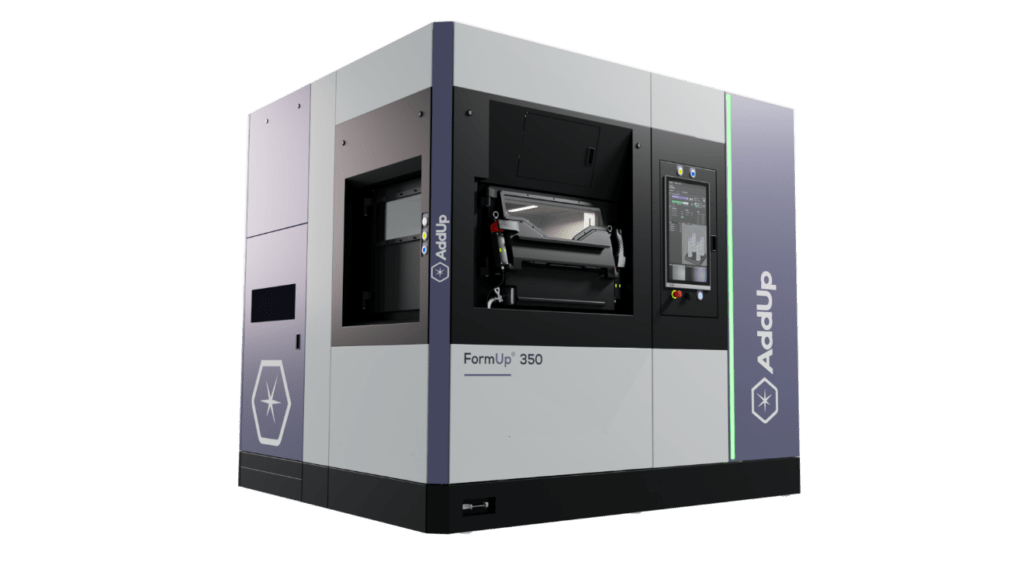

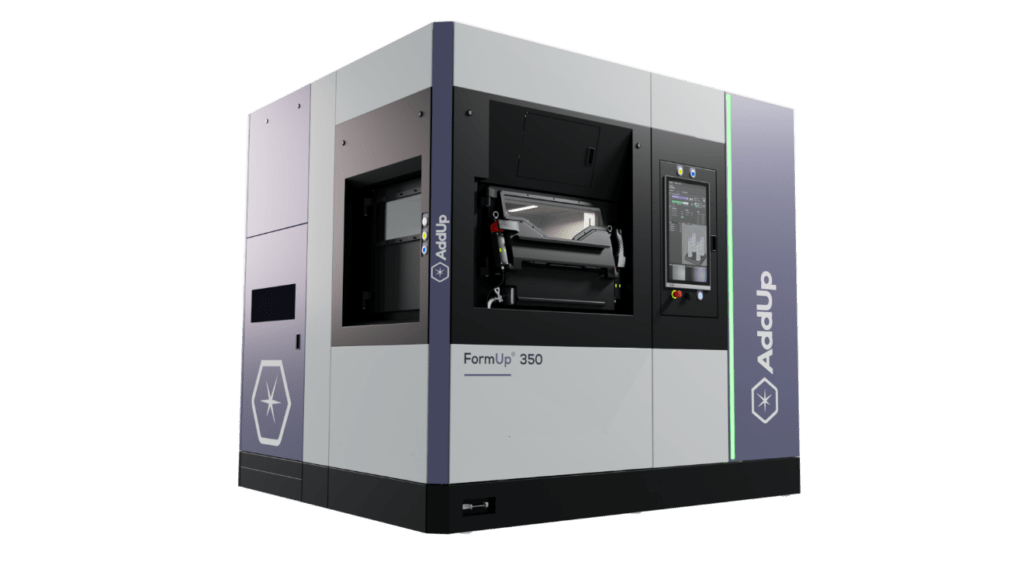

POWDER BED FUSION MACHINES

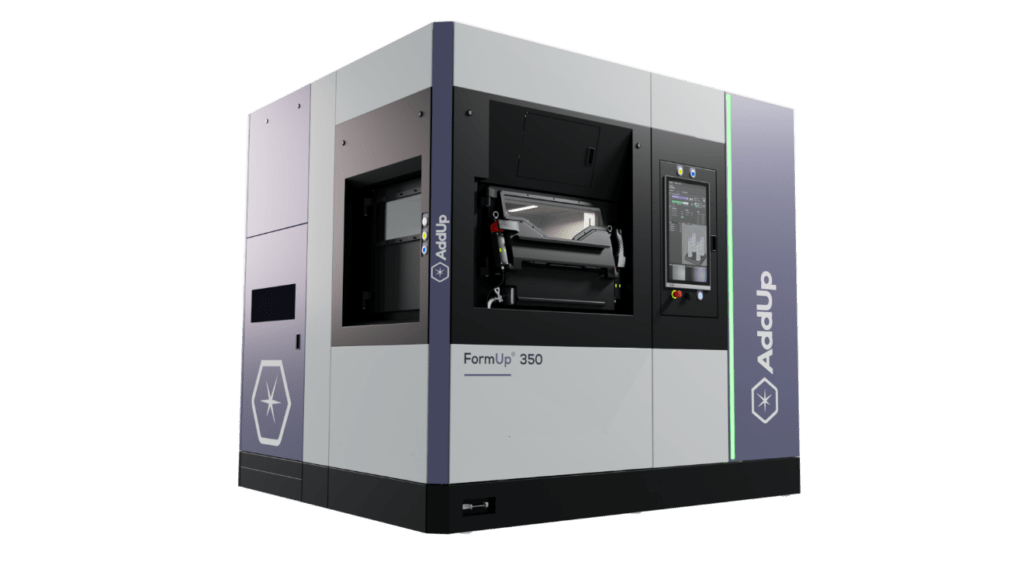

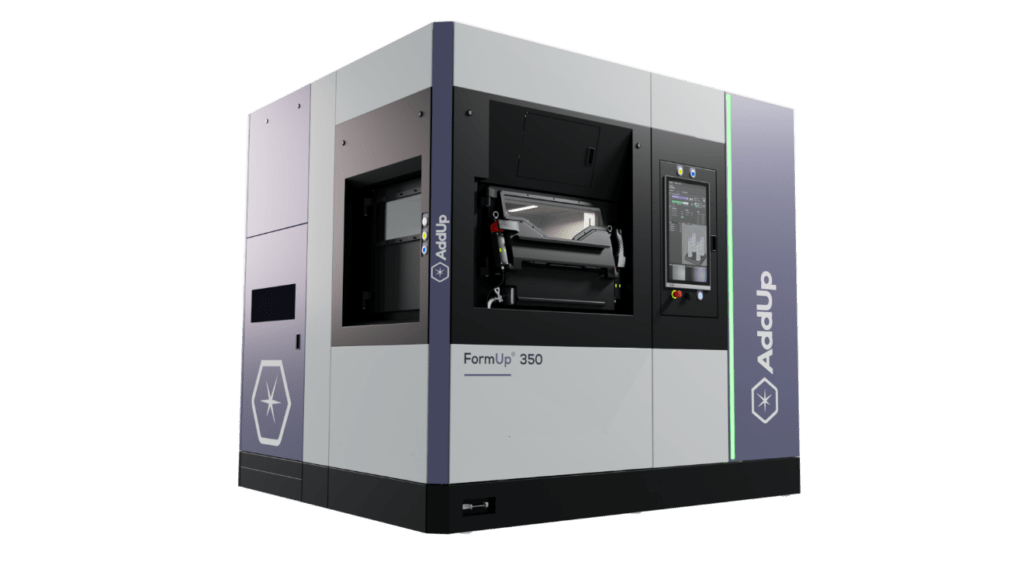

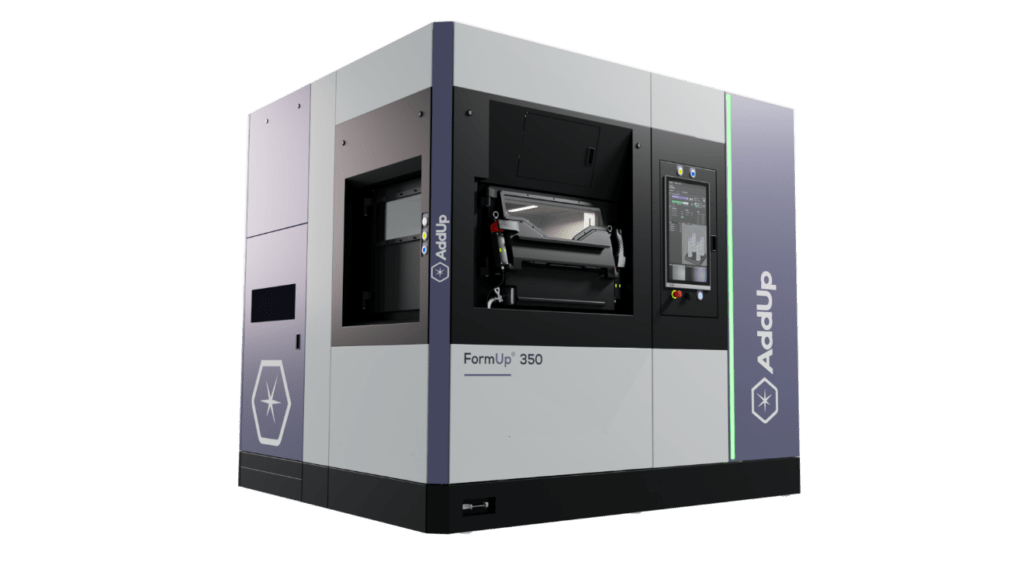

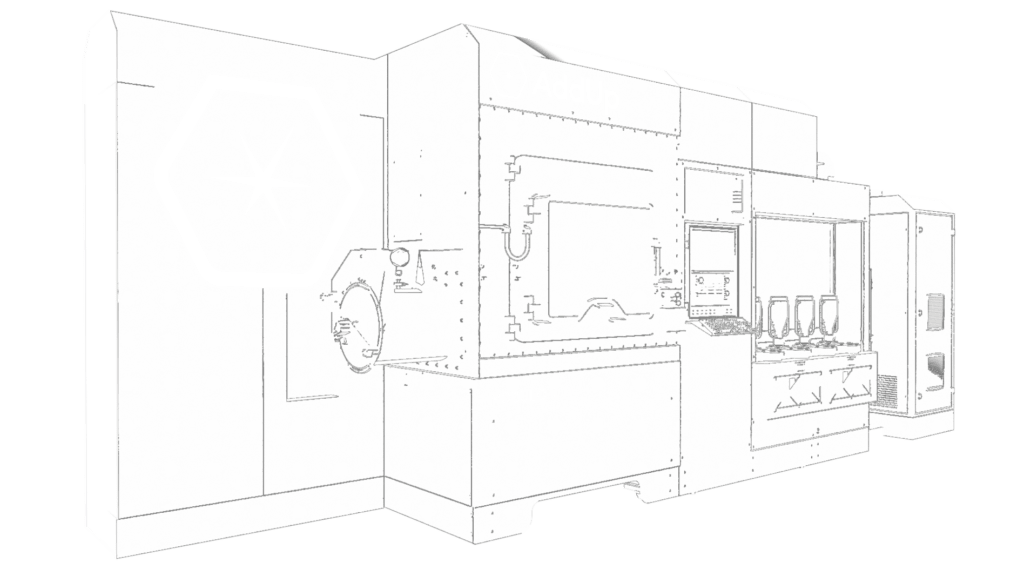

Our FormUp range of Powder Bed Fusion (PBF) machines are modular and scalable to provide high quality fine feature parts and industry leading productivity, all while adhering to the highest level of safety standards.

POWDER BED FUSION MACHINES

Our FormUp range of Powder Bed Fusion (PBF) machines are modular and scalable to provide high quality fine feature parts and industry leading productivity, all while adhering to the highest level of safety standards.

DIRECTED ENERGY DEPOSITION MACHINES

AddUp’s Modulo 400 and Magic 800 DED machines are designed for industrial production and are equipped with in-house designed and developed nozzles to optimize precision and productivity.

DIRECTED ENERGY DEPOSITION MACHINES

AddUp’s Modulo 400 and Magic 800 DED machines are designed for industrial production and are equipped with in-house designed and developed nozzles to optimize precision and productivity.

ADDITIVE MANUFACTURING SOFTWARE

Our suite of digital solutions focus on quality assurance and traceability, reducing the amount of post-production inspections needed and providing our customers increased confidence in part quality.

ADDITIVE MANUFACTURING SOFTWARE

Our suite of digital solutions focus on quality assurance and traceability, reducing the amount of post-production inspections needed and providing our customers increased confidence in part quality.

WE BUILD SMART MACHINES

From the industrial roots of our founding partner companies, Michelin and Fives, to technology built for the future, AddUp machines provide innovative solutions to manufacturers’ challenges.

Proud Heritage

AddUp combines Michelin’s expertise in industrial part manufacturing with Fives expertise in industrial machine design. We understand the world of manufacturing because we were born from it.

Proven Track Record

Our machines are repeatable and reliable. Every day parts are produced on AddUp machines. You can find them on satellites, aircrafts, trains, automobiles and even in the human body.

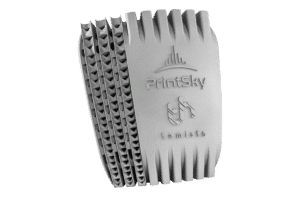

Better Surface Finish

Thanks to our roller recoater technology, you achieve a smoother surface finish with fine features and less supports, reducing your need for post-processing.

Open Parameter Machines

Some competitors keep the workings of their machines secret, but we don’t. Do more with our open platform where you can easily twist and turn the knobs as you see fit.

Safer Powder Handling

Our Autonomous Power Module (APM) takes care of the full powder management, limiting exposure to powder and making our machines safer for operators.

Quality Assurance Software

Our comprehensive suite of AM software and most advanced technologies offer traceability to provide you increased confidence in part quality.

Metal 3D Printing for Smart Industrial Manufacturing

INDUSTRY FOCUSWe work with contract manufacturers and OEMs on the things that matter most from increasing return on investment and reducing total cost of ownership to maximizing productivity and overall equipment efficiency. Our metal 3D printing machines were designed to provide maximum productivity and throughput in a serial manufacturing environment. Our reliable and repeatable platform coupled with in-process monitoring solutions provide peace of mind for manufacturers across a variety of industries and applications.

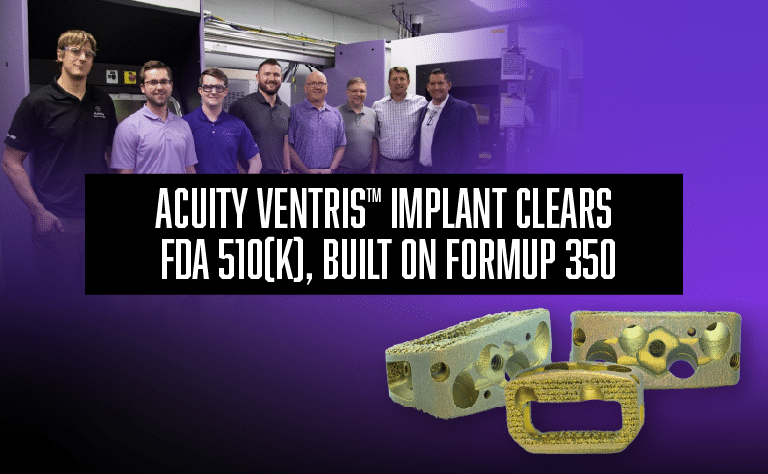

INDUSTRY FOCUSMedical

AddUp’s 4-laser PBF system reduces fusion times by up to 75%, when compared to single laser systems, providing maximum throughput to meet the demands of the medical device market. Thanks to our roller recoater technology, a smooth surface finish with fine features and lattice resolution is achievable directly as printed. This coupled with the ability to produce parts with little or no support structures reduces the need for post-processing and therefore overall costs for the device manufacturer.

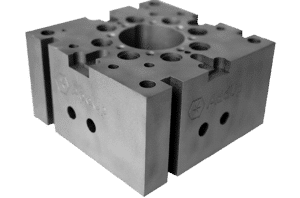

TOOLING, MOLDING & INDUSTRIAL

Our 3D metal printers take tooling molds and dies to the next level. The FormUp range of PBF machines have the ability to utilize a finer particle PSD and roller recoater technology to maximize the benefits of conformal cooling, reducing cycle time and improving part performance. Our DED machines can be used for tooling repair applications by building material atop an existing part to extend the overall life of the part.

AEROSPACE & DEFENSE

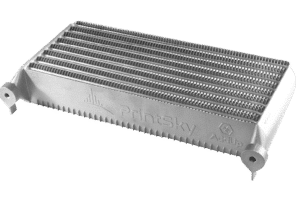

As an expert of two different additive technologies, AddUp has the unique ability to optimize aerospace applications using both PBF and DED. Our FormUp range of PBF machines are ideal for heat exchangers with thin walls and fine features and our BeAM range of DED machines are ideal for larger scale propulsion components such as rocket nozzles.

OTHER INDUSTRIES

Additive Manufacturing allows manufacturers across industries to produce innovative parts that they couldn’t make through traditional manufacturing. AddUp has expertise across a variety of other industries including automotive, motorsport, energy and luxury.

Metal Additive Manufacturing Applications

The use cases for Metal Additive Manufacturing are varied across different industries. See how AddUp customers have had success using our PBF and DED technologies.

Aerospace

Cassegrain Antenna

Ready-for-Flight Antenna in Powder Bed Fusion Thales Alenia Space is a french aerospace manufacturer that has played a significant role in space exploration for more than 40 years. As new […]

Michelin Tires Sipes

Discover how Michelin produces over one million tire sipes a year for their production molds using metal 3D printing When Michelin found that the metal AM machines on the market did not meet their high-quality…

Rocket Nozzle

AddUp optimized the design of a rocket nozzle to improve the performance of a micro-launch vehicle. Metal additive manufacturing can lead to fuel and production savings in aerospace. In this case…

Spine Implants

This case study focuses on spine implants and the challenges faced in their manufacturing process today. Additive Manufacturing (AM) offers benefits such as lattice design and surface roughness, leading to…

Aerospace

Isogrid Case Study

Combining Traditional Manufacturing with Additive – Adding Features with Directed Energy Deposition

Tooling

Gira Socket Injection Mold Case Study

An improvement in temperature control are guaranteed by employing intricate complex conformal cooling channels using the design freedom of AM.

Automotive

Multi-Metal, Multi-Technology Piston Head

This case study presents the development of multi-metal, multi-technology piston head The goal was to improve wear resistance and performance, as well as internal cooling channels.

Metal 3D Printing

FormUp Heat Exchanger

This case study presents the development of an optimized heat exchanger for the Form Up® 350 machine,. The goal was to improve heat dissipation and adapt the dimensions for easy installation.

Walking the Additive Manufacturing Journey With You

When you choose AddUp, you’re choosing a partner who will be with you every step of your journey. Whether you are in the early stages of adoption and looking to understand the benefits and capabilities of additive or are a mature user of the technology looking for a repeatable, reliable solution at scale; AddUp has the expertise and support team to guide you along your journey.

GOLD STANDARD OF SERVICESame day shipping turnaround for in stock parts

Average response time to customers

Average time to have a technician on-site for resolution

Our team helps new adopters understand the potential of Additive Manufacturing and how it can be applied to their business.

Once target applications have been identified, we work closely with our customers to develop and refine the application and their business case.

During this stage, we focus on qualifying the Additive Manufacturing process to meet industry-specific standards and regulations.

AddUp has the experience of building fully automated AM workshops. We have worked with customers to optimize their production lines using automation and we are ready to do the same for you.

“AddUp has demonstrated a set of capabilities that enable us to address unique design and application challenges faced by our growing base of aerospace, space, and defense customers.”

Greg Morris

“AddUp group has enabled our complex designs to become a reality using metal Additive Manufacturing, a state-of-the-art process. This will change the way we create and customize a motorcycle. Our creativity is now limitless, which was impossible with traditional metal manufacturing processes.”

Simon Dabadie

“The AddUp team has proven to live within their proclaimed values… delivering a beneficial experience, being a trusted partner, and encouraging innovation. As I navigate through projects, I have been impressed with the level of attentiveness and service they exhibit. Each interaction is laced with education, professionalism, and care.”

Shannon VanDeren

“The FormUp350 is one of the only machines on the market that can run both the typical LPBF powder cut and a much finer cut of powder. This gives us flexibility to meet certain challenging applications we may come across in the future.”

Rachel Levine

“The only French manufacturer of powder bed laser fusion machines (LPB-F) offering rare expertise both on the process and its applications with a machine capable of safely producing high quality parts in a repeatable and reliable way.”

Jean-Christophe Augé

“As an early adopter of AddUp machines, I really appreciate capabilities and proactive team spirit, to deliverer parts in a serial mode.”

Aurelien Fussel

“We chose AddUp as our machinery partner for our recent project due to their High-Quality Products and Innovative Technology. AddUp’s commitment to research and development leads to cutting-edge solutions, like the Modulo 400 system, which offers versatility and high-quality results. This aligns perfectly with our vision at the Application Center for Additive Manufacturing at Research Institutes of Sweden AB, where we aim to lead in applied research and collaborate on new materials and solutions for the market.”

Seyed Hosseini

“AM is in a state of exponential growth with the biggest challenges in adoption being qualification and certification. NSL is focused on partnering with companies who are passionate about driving innovation for metal 3D printing.

Over my past three years working with AddUp they have demonstrated a commitment to industrializing additive technology. The evolution of the FormUp 350 has made significant advancements in its full-field, 4-laser system and its monitoring suite which helps to accelerate the qualification process. Advancements like this prove AddUp to be a major player in the growing AM industry.”

Ed Herderick

“With AddUp as a partner, we are trying to push metal 3D printing technology to its limits in terms of part sizes and associated material health. The quality of AddUp’s printing systems as well as the expertise and motivation of the teams have allowed us to move forward in an open and efficient way.”

Francois Billig

“AddUp’s proprietary technology is a game changer for the medical AM space. Their quad-laser system can print our parts up to 4x faster, and look much better than other platforms we were previously printing on. Our partnership with AddUp has been instrumental in our success and future growth.”

David Nutter

“The FormUp 350 is a dream come true for us. It’s on the cutting edge from both a software and hardware perspective. The large build volume and quad laser system allow us to get production jobs done faster than the competition, while the roller recoater lets us push the design envelope to the next level.”

Noah Smith

Step into The Future of Metal Manufacturing

Today’s metal 3D printers unlock designs impossible with conventional methods, offering unparalleled precision and complexity. Blending groundbreaking innovation and expertise, AddUp is leading the evolution of metal additive manufacturing