Certified Excellence in Additive Manufacturing: AddUp’s Qualifications

AddUp operates with a strong focus on quality, efficiency and customer-centricity. AddUp’s processes and systems have been reviewed and validated for compliance to applicable ISO standards. This means that independent third parties have qualified AddUp’s systems and processes in accordance with the defined requirements. We believe our certifications enhance our reputation and credibility, an important aspect to earning the trust of our customers.

ISO standards are important because they provide an internationally recognized standard framework for the systems and processes that make up AddUp’s operations. These standards define many accepted requirements, including those for the management of customer expectations and feedback, management of practices related to internal and external quality, management and mitigation of risks and the need for continuous improvement.

AddUp is certified to:

| INDUSTRY | QUALITY STANDARDS | CERTIFIED LOCATION | OVERSIGHT AGENCY |

|---|---|---|---|

| Aerospace | ISO9001:2015 / EN9100:2018 | AddUp SAS (EU) | EUSPA |

| Environmental | ISO14001:2015 | AddUp SAS (EU) | EEA |

| Defense | CMMC | AddUp Inc (US) | DOD |

| Defense | ITAR | AddUp Inc (US) | DOS |

ISO 9001:2015 / EN9100:2018

ISO 9001:2015 is an international standard focused on quality management systems, ensuring organizations consistently meet customer and regulatory requirements.

EN9100:2018 defines the additional requirements (beyond those of ISO 9001:2015) which are applicable to suppliers of the Aerospace Industry. AS9100 is applicable to such suppliers in the United States, while EN9100 is applicable to suppliers in the European Nations.

Depending on locations and markets served, aerospace suppliers are required by regulatory authorities to comply with the requirements of EN9100. AddUp’s quality management systems and EN9100 certification make us a credible support partner and supplier to manufacturers which must comply with those requirements.

ISO 14001:2015

ISO 14001:2015 sets out the criteria for organizations to identify and control their environmental aspects, establish environmental objectives and targets, and demonstrate continuous improvement in their environmental performance.

AddUp’s Environmental Management System and ISO14001 certification provide assurance to company management and employees as well as external stakeholders that our environmental impact is being measured and improved.

CMMC

CMMC certification addresses the crucial aspect of cybersecurity within the USA. This certification assures that sensitive data is protected and ensures the integrity of critical information.

With CMMC certification, AddUp can demonstrate to potential buyers that they have implemented appropriate cybersecurity measures to safeguard information related to defense contracts or other controlled unclassified information (CUI). This certification instills confidence in AddUp’s ability to protect buyers’ proprietary designs, ensuring the security and confidentiality of projects.

ITAR

ITAR registration and certification assures that a company is adhering to strict regulations concerning the export and import of defense-related articles and services. This certification ensures that parts are produced within a secure environment, safeguarding sensitive information and intellectual property.

To support the defense and aerospace sectors in the USA, ITAR compliance and certification is vital for manufacturers.

With ITAR certification, potential buyers in the defense sector know they can trust AddUp to handle sensitive projects, reinforcing confidentiality and security.

WHY ADDUP

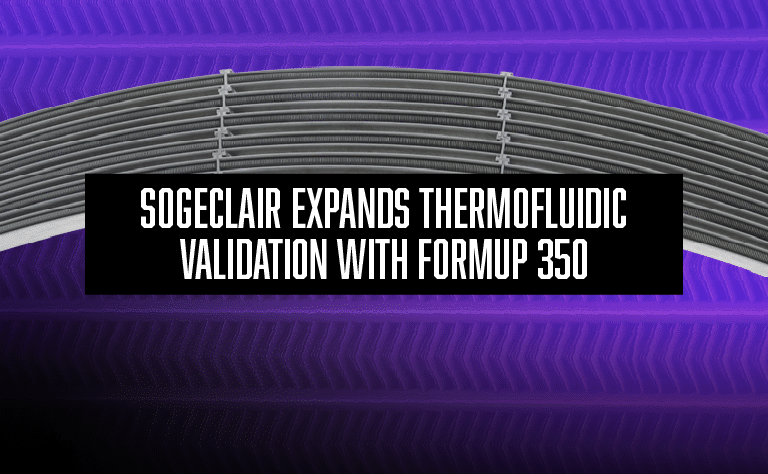

AddUp is an expert of two metal AM technologies built off more than 200 years of industrial experience. When you choose AddUp, you’ll experience best in class safety on a repeatable, reliable platform. AddUp machines offer a host of technological advantages working in synergy to produce the very best products – without compromising quality or productivity.

LEARN MOREIndustries We Serve

AddUp’s reliable and repeatable platform coupled with in-process monitoring solutions provide peace of mind for manufacturers across a variety of industries and applications.

Medical

AddUp’s 4-laser PBF system reduces fusion times by up to 75%, when compared to single laser systems, providing maximum throughput to meet the demands of the medical device market. Thanks to our roller recoater technology, a smooth surface finish with fine features and lattice resolution is achievable directly as printed. This coupled with the ability to produce parts with little or no support structures reduces the need for post-processing and therefore overall costs for the device manufacturer.

TOOLING, MOLDING & INDUSTRIAL

Our 3D metal printers take tooling molds and dies to the next level. The FormUp range of PBF machines have the ability to utilize a finer particle PSD and roller recoater technology to maximize the benefits of conformal cooling, reducing cycle time and improving part performance. Our DED machines can be used for tooling repair applications by building material atop an existing part to extend the overall life of the part.

AEROSPACE & DEFENSE

As an expert of two different additive technologies, AddUp has the unique ability to optimize aerospace applications using both PBF and DED. Our FormUp range of PBF machines are ideal for heat exchangers with thin walls and fine features and our BeAM range of DED machines are ideal for larger scale propulsion components such as rocket nozzles.

OTHER INDUSTRIES

Additive Manufacturing allows manufacturers across industries to produce innovative parts that they couldn’t make through traditional manufacturing. AddUp has expertise across a variety of other industries including automotive, motorsport, energy and luxury.

Get Started with AddUp

Realize the potential digital manufacturing has to offer. Get started with AddUp and learn how AM delivers innovative solutions to solve manufacturers toughest challenges.