L-PBF for Medical Implants

OEMs and contract manufacturers are scaling medical implant production with AddUp’s FormUp 350 because it’s delivering FDA-cleared parts, proven batch consistency, and reliable process control. If your current platform can’t meet regulatory scrutiny or keep up with market demand, it’s time to see what’s actually working in real-world medtech.

See it in Action

See how the FormUp 350 delivers the throughput and Overall Equipment Effectiveness that you need.

Acetabular Hip Cup: 21,735 cups/year per machine. 78% OEE. >99.9% density.

Spinal Implants: 152 implants per build. 99.95% density.

All Case StudiesACETABULAR HIP CUPS

This case study details the use of Laser Powder Bed Fusion (LPBF) to manufacture acetabular cups for total hip replacements. The focus: maximize throughput, cut lead times, and improve implant quality over traditional methods.

Read More

Objectives:

- Increase production efficiency for hip cups using LPBF.

- Improve implant quality and reduce manufacturing bottlenecks.

Challenges Overcome:

- High surface roughness and long lead times with casting/EBM.

- Expensive, hard-to-validate porous coatings in traditional manufacturing.

Results:

- Up to 21,735 cups/year per FormUp 350 (4-laser, 30µm layer).

- 78% Overall Equipment Effectiveness (OEE), >99.9% part density, support-free builds reduce post-processing and cost.

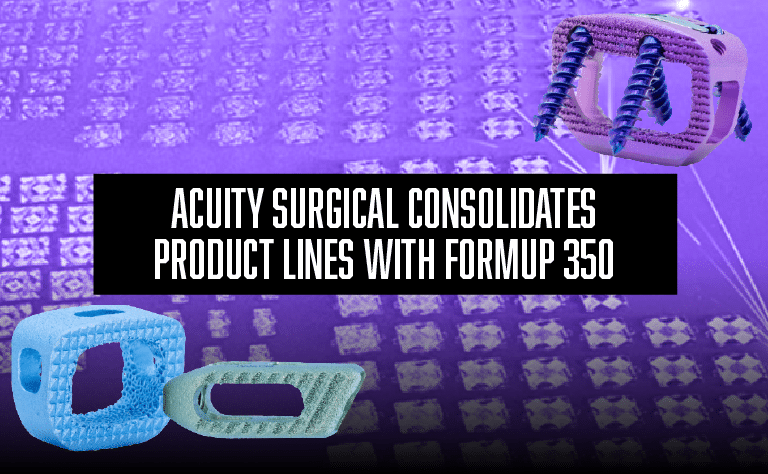

SPINAL IMPLANTS

This project showcases the FormUp 350’s ability to serially produce spinal cages with intricate features, maintaining consistency and regulatory standards.

Read More

Objectives:

- Deliver high-density, structurally optimized spinal cages.

- Enable batch production with repeatable quality.

Challenges Overcome:

- Meeting geometric tolerances for complex lattice structures.

- Ensuring high-density and mechanical strength in every build.

Results:

- Up to 152 spinal implants per build.

- Density up to 99.95%; accuracy within ±0.05 mm; efficient support removal for downstream validation.

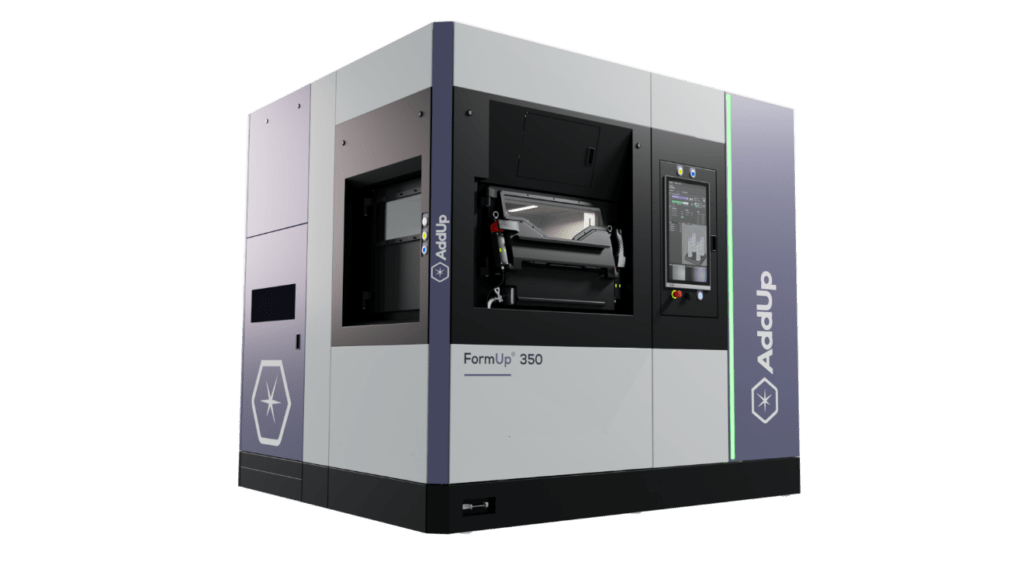

FormUp 350

Every one of these medical implant successes was made possible by the FormUp 350. Its high-resolution printing, robust process control, and scalable 4-laser architecture allow reliable, repeatable production of complex, patient-ready implants. Advanced powder handling and strict safety measures make it a dependable choice for manufacturing critical medical devices, whether the goal is serial production or rapid turnaround for patient-specific cases.

FormUp 350

Every one of these medical implant successes was made possible by the FormUp 350. Its high-resolution printing, robust process control, and scalable 4-laser architecture allow reliable, repeatable production of complex, patient-ready implants. Advanced powder handling and strict safety measures make it a dependable choice for manufacturing critical medical devices, whether the goal is serial production or rapid turnaround for patient-specific cases.

Get the Tech Specs