Technical Specifications

| Technical Specifications | |

|---|---|

| Dimensions | L 11x W 5 x H 5 |

| Build volume | L 750 x W 750 x H 1000* mm |

| O2 level | 500 ppm |

| Laminar flow | Adjustable from 0.5 to 3 m/s |

| LASER lens protection | Dedicated gas flow |

| Optical Chain | Up to 12 x 500W or 1000W Ytterbium continuous fiber LASER (1070 nm) |

| Spot diameter: 70±5 µm | |

| Advanced Overlap management | |

| 3D scanners: 2 axis for X/Y displacements + 1 axis for focal adjustment | |

| Max speed: ≤ 10m/s | |

| Accuracy: 35 µm | |

| Platform | Heating system: up to 200°C |

| Cooling system to improve temperature drop time after production | |

| Automatic clamping system with 100% of the platform surface available | |

| Part Properties | Precision: up to 0.1 mm** |

| Density: up to 99.99%** |

| Powder Handling | |

|---|---|

| Powder type | All, reactive & non-reactive, included fine size powders* |

| Powder capacities | Principal module (main tank): 850L |

| Powder container (85L) | |

| Machine buffer tanks: 15 L | |

| Powder recoating device | Bidirectional Scraper (carbon brushes or silicon blade) |

| Bidirectional Roller (option) | |

| Interchangeable | |

| Layer thickness: 20 to 120 µm | |

| Autonomous Powder Module | Feeds powder to the machine |

| Re-filling possible during production | |

| Powder humidity removal & fluidification | |

| Ensures inert condition during powder conveying and storage | |

| Powder recovery from build surplus & recycling (closed loop) | |

| Sieve and regenerate powder | |

| Powder vacuum inside build chamber & recycling | |

| Drains powder from the machine | |

| Ensure safety with “no powder contact” | |

| Siever type | Ultrasonic (adjustable mesh) |

| Fume and fusion residue management | Filtration device with automatic unclogging sytem |

| Calcium carbonate residue passivation | |

| Filters lifetime > 3 years | |

| Cooling device | Air / water (independant) or connection to workshop water circuit (option) |

| Connections | |

|---|---|

| Exhaust | Air / inert gas mixture |

| Flowrate: 660 NL/min | |

| Connection: smooth sleeve Ø4” OD | |

| Fan to force extraction (option) | |

| Filtration: HEPA13 | |

| Must be evacuated outside of the building | |

| Gas | Argon or nitrogen |

| Argon purity >99.998% according to ISO 14175-l1-Ar | |

| Nitrogen purity >99.97% | |

| Pressure: 4 to 5 bar | |

| Maximum flowrate: 660 NL/min | |

| Minimum setpoint: 500 ppm | |

| Gas consumption (production): 2.5 NL/min (at 500 ppm O2 level) |

|

| Connection: for pipe Ø12 OD | |

| Compressed air | Air purity: class 4 for category B (water) and class 3 for other categories (solid particles and oils) - according to ISO 8573-1:2010 |

| Pressure: 5 to 7 bar | |

| Maximum flowrate: 100 NL/min | |

| Nominal (prod.): 25 NL/min | |

| Connection: for pipe Ø12 OD |

| Traceabillity | |

|---|---|

| Interoperability | OPC-UA / MQTT (option) |

| CAM solutions | AddUp Manager or NTwin |

| Simulation software | Distortion Simulation AddOn (option) |

| Monitoring | AddUp Dashboards (option) |

| Recoating monitoring (option) | |

| Melting monitoring (option) | |

| Remote Maintenance | AddUp Remote Control |

| MyAddUp 24/7 online platform | |

| Visualization | Supervision camera for live stream |

| HD camera for pictures (option) |

Smart Software

AM is an incredibly advanced technology to master due to the various scales we must deal with, generating millions of vectors corresponding to miles of trajectories, at a speed of several meters per second, being drawn by a “pencil” having a diameter of a hair. Many components such as the platform, laser, air flow, for inerting conditions will have to work together to create the part as desired. To assure all these components are working in synergy, AddUp offers an end-to-end solution to its customers, with many flexibilities:

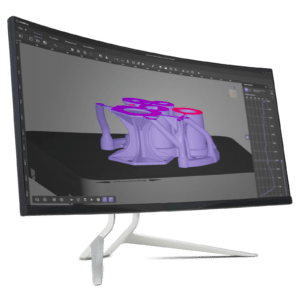

ADDUP MANAGER

Easy-to-use CAM software that can manage large 3D files with high resolutions levels and accurate production time estimates. AddUp Manager also provides access to advanced print and recoating strategies to improve surface finish.

NCORE

The brain behind the machine. NCore allows you to generate your own productions check lists, so that your staff will have everything before they can launch a production. It also gives a fully traceable dataset of the print generating pictures of after melting and recoating along with live access to a camera with remote control.

ADDUP DASHBOARDS

Based on Grafana, a fully customizable data visualization solution, AddUp Dashboards provides hands-on machine conditions. Create your own visualization sets, define variables you want to see and set your conditional alerts. Read and write administration can also be set to adjust different needs for different profiles.

RECOATING MONITORING

The Recoating Monitoring system prevents production stops from recoating. This solution, based on picture analyses, automatically detects flaws during production, including powder drops or lack of powder, for example. KPIs are also directly available in the AddUp Dashboards, so you can set up alerts.

MELTPOOL MONITORING

The Meltpool Monitoring system allows you to track spatial and temporal information including Power, IR, Positions, and laser status. There is real-time visualization of the production condition at micro-scale, with unique possibilities to improve process performance and track parts quality.

YOUR MACHINE. YOUR IP.

Thanks to the open approach of our software, our customers can develop complex parameterizations to meet their most demanding requirements.

Respect for our customers’ intellectual property created with AddUp solutions is at the heart of our concerns. That’s why AddUp guarantees total watertightness of information within the machine and requires no Internet connection or information sharing under production conditions.

For customers who so wish, AddUp offers a remote maintenance option based on high-level secure solutions.

BEYOND THE MACHINE

AddUp experts are ready to support you throughout your AM journey. Even after your machine is up and running, our team is committed to providing a gold standard of service. We pride ourselves on our industry leading response times and strive to exceed customer expectations by delivering exceptional experiences. You can count on AddUp to be the partner you rely on to consistently deliver high-quality service.