Blagnac and Cébazat, France – Building on nearly a decade of collaboration, SOGECLAIR and AddUp, a subsidiary of Fives Group, are taking a new step forward with SOGECLAIR’s acquisition of a FormUp 350 metal 3D printing machine. This move follows the creation of the PRINTSKY joint venture in 2016, dedicated to developing industrial projects and advancing the maturity of metal additive manufacturing for the Aerospace, Space, and Defense sectors. The installation of AddUp’s FormUp 350 at SOGECLAIR’s Toulouse site will accelerate the integration of metal 3D printing into its industrial production processes.

Towards a complete value chain in additive manufacturing

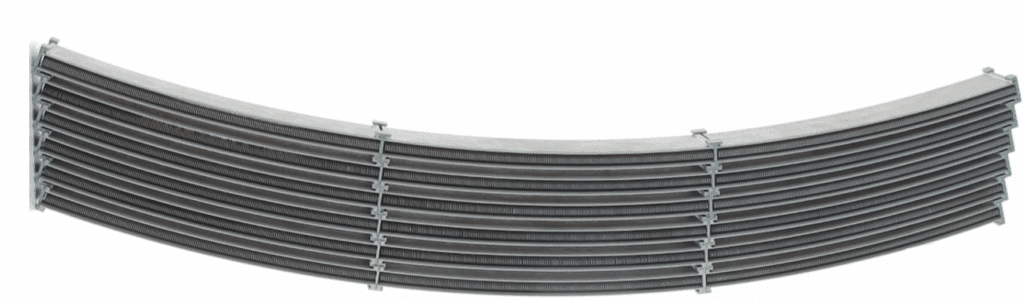

This deployment marks a key milestone in SOGECLAIR’s development as a provider of complex solutions and confirms its commitment to accelerating the industrialization of technical parts using metal additive manufacturing. With strong expertise in design and industrialization, SOGECLAIR develops and manufactures high-value-added components, including thermal equipment that meets the demands of current and next-generation aircraft.

The FormUp 350 will complement SOGECLAIR’s thermofluidic equipment test bench, which simulates thermal cycles and multi-fluid stresses experienced by heat exchangers. This ensures the reliability and performance of parts produced using this complex technology, addressing future industrial challenges.

Stéphane ZIRILLI, VP SOGECLAIR EQUIPMENT Innovative Materials: “Integrating this machine from AddUp’s FormUp range marks a major milestone. It enables us to offer our clients a complete solution, from design to qualification of complex parts, including series production. This is a key step toward realizing our industrial ambitions.”

SOGECLAIR already has experience with the FormUp 350, as demonstrated by the success of the ECCAD project, funded by CORAC of the DGAC. This aluminum heat exchanger, designed for aerospace, features thin walls (down to 150 µm) and double-curved channels that are impossible to produce using conventional techniques.

The FormUp 350 enables the production of parts with complex geometries and advanced mechanical performance. Its multi-laser powder bed fusion (L-PBF) technology and real-time monitoring system ensure consistent quality, essential for critical components exposed to extreme environments. Its ability to optimize part topology allows for lightweight structures without compromising robustness, a major advantage for Aerospace, Space, and Defense. High-precision surface finishing (up to 4 μm Ra) enhances thermal and fluidic performance, while its closed systems ensure safe powder handling, compliant with strict traceability and safety standards for critical applications.

An industrial alliance serving critical systems

Julien Marcilly, President of AddUp: “Our long-standing partnership with SOGECLAIR perfectly illustrates our commitment to supporting manufacturers in their transition to additive manufacturing. Through our technological expertise and LevelUp service program, we support them in strengthening their capabilities and meeting the demands of the Aerospace and Defense sectors. This strategic collaboration allows us to consolidate our position in critical applications and co-develop the industrial solutions of tomorrow.”

With the integration of the FormUp 350, SOGECLAIR enhances its ability to offer a complete value chain: from designing parts optimized for additive manufacturing to their production, qualification, and validation on its thermofluidic test bench. This integrated approach meets the requirements of critical systems, particularly in Aerospace, Space, and Defense. It also aligns with an industrial transformation toward innovative, reliable, and sustainable production processes, positioning SOGECLAIR as a key player in the industrialization of high-value-added solutions.

AddUp, with collaborations involving Dassault Aviation, Thales, and the DGA, has recognized expertise in Aerospace, Space, and Defense. Strategic projects such as MASSIF, focused on developing a new machine for large-scale part production and supported by the France 2030 program, or sending a machine to the International Space Station, demonstrate the maturity and robustness of its solutions for critical applications.

Together, AddUp and SOGECLAIR are combining their expertise to accelerate industrial adoption of additive manufacturing and pave the way for a new generation of critical solutions for Aerospace, Space, and Defense.

###

ABOUT SOGECLAIR

A provider of innovative, high-value-added solutions for more sustainable and safer mobility, SOGECLAIR offers high-quality engineering and manufacturing expertise to advanced sectors: aerospace, space, automotive, rail, and defense. Supporting clients and partners from design and simulation to end-of-life, across the entire manufacturing and commissioning chain, its teams are located worldwide to provide close and high-quality support to all customers.

SOGECLAIR is listed on Euronext Growth Paris – Euronext® Family Business Index – ISIN Code: FR0000065864 (Reuters SCLR.PA – Bloomberg SOG.FP)