AdditiveLab, a leader in simulation software development for metal additive manufacturing (AM), has teamed up with AddUp, a global metal additive manufacturing OEM, to release the latest version of AddUp Manager. This advanced build preparation software for metal 3D printing now includes a powerful simulation engine, specifically designed to streamline and optimize the production process on the FormUp 350 Powder Bed Fusion machine.

AddUp Manager, known for its comprehensive build preparation capabilities, allows users to fine-tune over 250 variables and parameters, create custom melting strategies, and visualize laser trajectories. The latest release, version 7.6, integrates an intuitive and efficient simulation module, enhancing precision and flexibility for high-quality metal 3D printing.

With a decade of experience, AdditiveLab understands the challenges companies face when adapting AM technology at an industrial level, particularly in optimizing manufacturing success. “We are excited to partner with AddUp because their customers use metal AM for challenging designs at a serial production level. Our software integration will help AddUp customers overcome production challenges, enabling them to manufacture complex designs more efficiently.” said Christian Rossmann, AdditiveLab CEO. “This partnership presented an excellent opportunity to collaborate and make an impact on industrializing metal AM.”

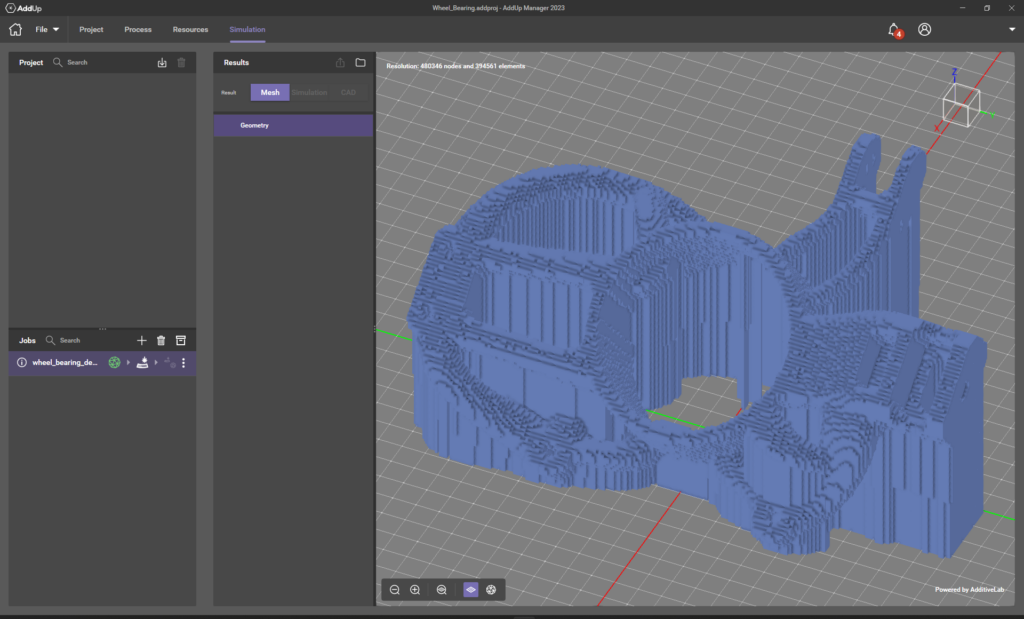

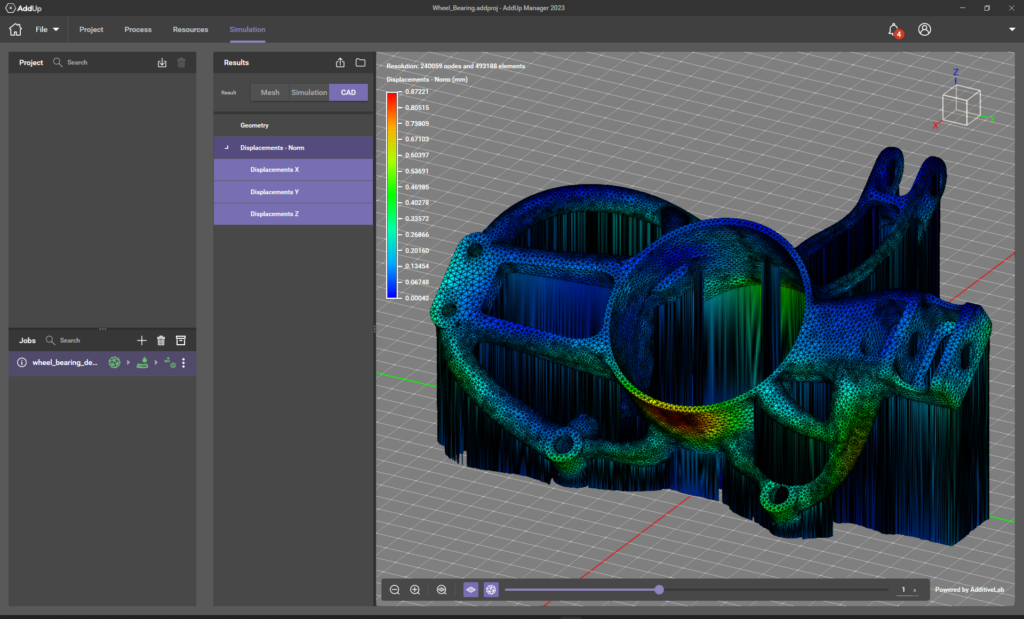

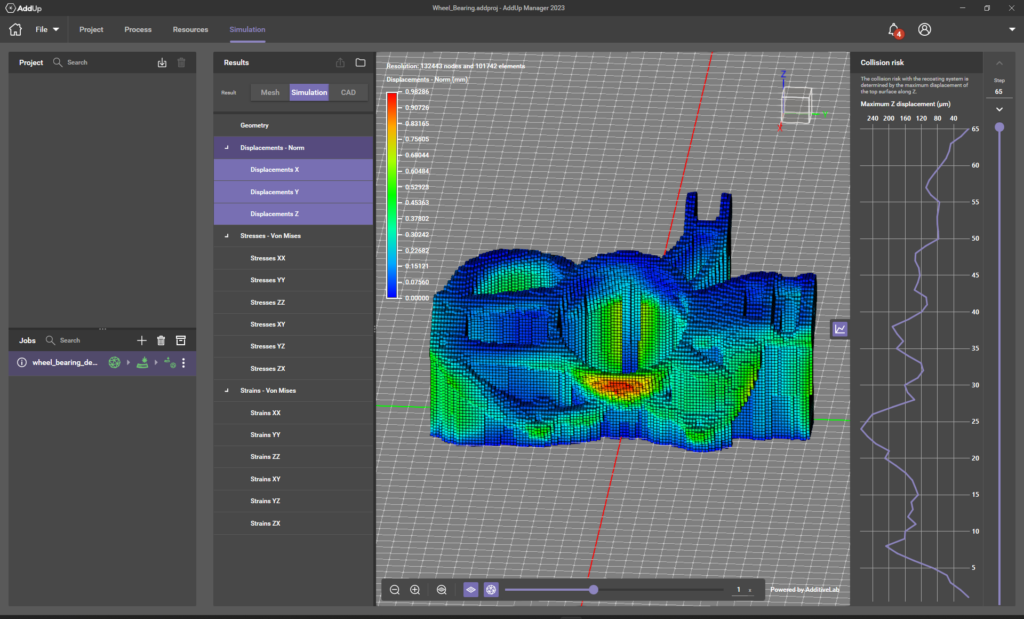

Simulation software is crucial in metal 3D printing for predicting stresses and deformations in the build before printing begins. By anticipating and correcting these issues, manufacturers can significantly reduce errors and increase success rates. The new simulation software integrated into AddUp Manager 7.6 offers a fast, accurate, and user-friendly solution for optimizing scanning strategies and understanding the intricate details of the additive manufacturing process.

Wheel Bearing Simulation from AddUp Manager 7.6

Many metal 3D printing users have had to rely on separate software for build preparation and simulation, which increases costs as well as the potential for overlooked deformations or errors across platforms. The integration of a simulation engine within AddUp Manager simplifies the build preparation process, providing a unified platform that enhances efficiency and reduces the learning curve associated with multiple software tools.

From AddUp’s perspective, the collaboration was a clear choice. “After testing multiple options, the result from AdditiveLab was superior. Their simulation software was very simple to use and provided an easy way to integrate functionality into AddUp Manager” explained Sebastien Devroe, AddUp’s Chief Technology Officer. “The partnership with AdditiveLab ensures our customers have a seamless and efficient user experience.”

About AdditiveLab:

AdditiveLab is a leading provider of advanced simulation software for metal additive manufacturing (AM). Founded with the mission to enhance the efficiency and reliability of AM processes, AdditiveLab specializes in developing tools that predict and optimize manufacturing outcomes. Their state-of-the-art simulation technology is tailored to meet the needs of process engineers, design engineers, researchers, and scientists in the AM field.

Their flagship product, AdditiveLab RESEARCH, offers robust solutions for simulating Powder Bed Fusion (PBF) and Direct Energy Deposition (DED) processes. It enables users to predict deformations, assess stress concentrations, and optimize build configurations. The software’s intuitive interface, combined with its powerful Python API, allows for extensive customization and automation, making it accessible to both novices and experts in AM simulation.

AdditiveLab’s tools are designed to minimize trial-and-error in the production process, saving time and resources while improving the quality of manufactured parts. With a strong focus on scalability and ease of use, AdditiveLab ensures that their solutions integrate seamlessly into existing workflows, providing critical insights into thermal and mechanical behaviors during the AM process. For more information, visit: www.additive-lab.com.