AddUp has expanded its material portfolio by adding Constellium’s Aheadd CP1 aluminum alloy to its FormUp® 350 machines, offering a high-performance alternative to traditional aluminum alloys for additive manufacturing.

Constellium’s Aheadd CP1 alloy can now be used on AddUp FormUp® 350 machines. This aluminum alloy is specially developed for the needs of additive manufacturing and it is an interesting alternative to traditional grades such as AS7 or AS10, with higher productivity and better performance for heat dissipation applications.

AddUp qualified a new aluminum alloy Aheadd CP for FormUp 350 machines. This alloy was developed by Constellium and was designed for the needs of additive manufacturing by laser powder-bed fusion (L-PBF) specifically for high-performance and lightweight applications.

The current AM market is dominated by AS7 and AS10 grades (alloys of aluminum, silicon and magnesium, originally created for the foundry industry). Constellium offers an aluminum-iron-zirconium alloy with higher solderability which makes it possible to increase laser power and scan speed and therefore to improve productivity. The gains can range depending on the type of part to be printed, and more could be achieved in the next years.

Above all, with Constellium alloy, post-build operations are simplified. “To obtain the best mechanical properties using AS7 and AS10 grades, several long and expensive post-build treatments must be carried out, such as hot isostatic pressing and, solution and aging Etc,” explains Frédéric Sar, Materials Officer at AddUp. “With Aheadd CP1, very similar material properties can be achieved with a simple heat treatment at 400°C.” Saving time and money on these post-printing operations, which represent up to 40 to 50% of the cost of L-PBF parts, can make a difference in the profitability of an application.

In detail, the mechanical properties of parts made by AddUp from Aheadd CP1 (particle size 20-63 µm) are close to those of AS7 in terms of hardness, at least equivalent in fatigue resistance and higher in ductility. These parts are also compatible with anodizing treatments to improve corrosion resistance.

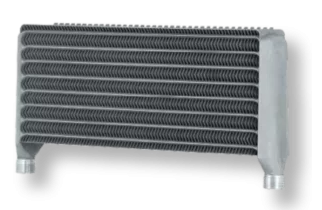

Improved Thermal Conductivity

Higher thermal conductivity of Aheadd CP1 compared to traditional aluminum alloys makes Constellium’s alloy a better candidate for all heat exchanger applications. This alloy is stable up to 250°C without degrading its microstructure. Therefore the parts made out of this material can be used at higher temperatures compared to AS7, which paves the way for lightweight applications for the aerospace industry.

All these characteristics make Aheadd CP1 a potential alternative to AS7 and AS10 alloys for 3D printing. This material was recently approved in the field of motorsports. Combining this material with performance of the AddUp FormUp 350 machine, increases the productivity without compromising the part quality. This material could quickly gain significant interest in many other industrial sectors, including aeronautics and aerospace.