This article discusses the importance of powder handling in Laser Powder Bed Fusion (LPBF) technology and introduces AddUp’s Autonomous Powder Module (APM) as a comprehensive closed-loop solution.

Written by: Mark Huffman, Application Engineer – Aerospace & Defense

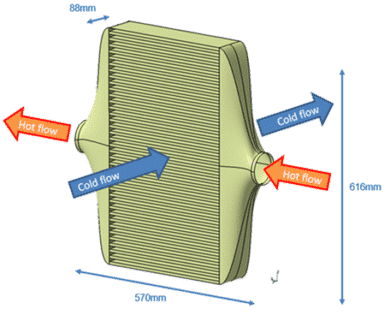

Laser Powder Bed Fusion (LPBF) technology has revolutionized the manufacturing industry by allowing the production of complex geometries with high precision and accuracy. LPBF technology involves the melting and solidification of metallic powder through the use of a high-powered laser beam, which fuses the powder particles layer by layer to create the desired part. However, the quality and reliability of the final part heavily depends on the quality of the powder used and how it is handled.

Powder handling is a critical aspect of the LPBF process that involves the transportation, storage, and handling of metallic powder. The quality of the powder can be affected by various factors such as humidity, temperature, particle size, and the presence of contaminants. The following are some of the reasons why powder handling is important when using LPBF technology:

The Problem

Quality Control

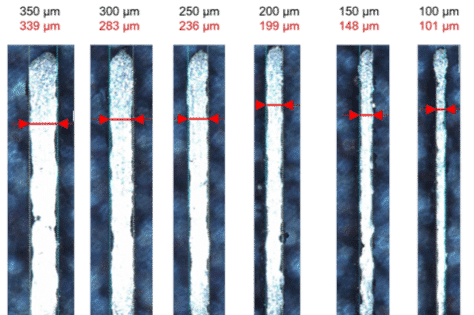

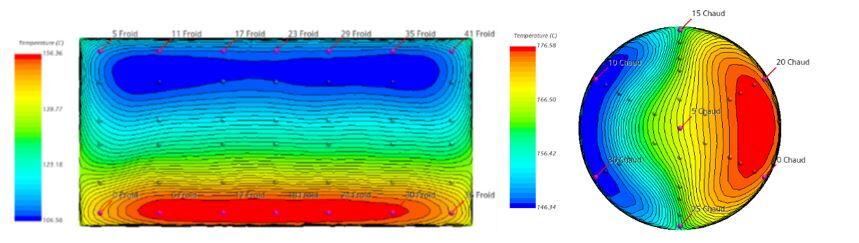

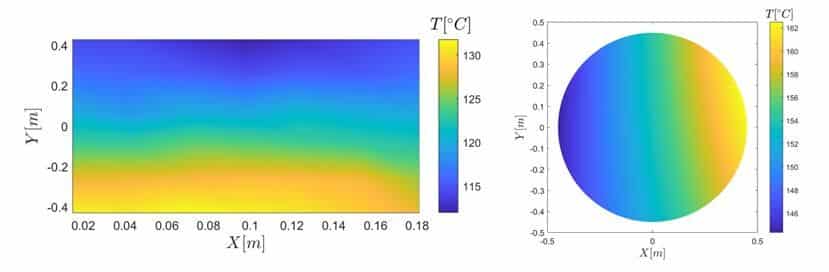

The quality of the powder used in the LPBF process has a significant impact on the final part’s quality and reliability. Therefore, proper powder handling procedures must be implemented to ensure that the powder is of the required quality. This includes proper storage conditions, such as temperature and humidity control, as well as regular inspection and testing to ensure that the powder is still meets your powder specification for PSD, chemistry and morphology that could affect the final part’s properties.

Process Control

Proper powder handling also ensures that the LPBF process is consistent and repeatable. Inconsistent powder quality can result in variations in the melting and solidification process, leading to defects in the final part. Therefore, it is essential to implement powder handling procedures that ensure the powder is homogeneous, and the particle size distribution is within the required range.

Safety

Metallic powders used in the LPBF process can be hazardous if not handled properly. Some powders are flammable, explosive, or can cause respiratory problems if inhaled. Proper handling procedures such as using personal protective equipment, good ventilation, and ensuring the powder is grounded can minimize the risks associated with handling metallic powders.

Cost

The cost of metallic powder used in the LPBF process is relatively high. Proper powder handling procedures can help minimize powder waste and ensure that the powder is used efficiently. This includes proper transportation, storage, and dispensing of the powder to reduce spills and contamination.

Powder handling procedures ensure that the quality of the powder is maintained, the LPBF process is consistent and repeatable, safety is prioritized, and costs are minimized. Continually implementing powder handling procedures, technology, and equipment that adhere to industry standards is essential to ensure that the LPBF process is optimized, resulting in high-quality and reliable parts.

The Solution

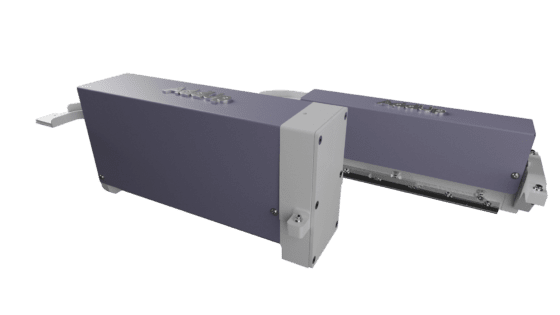

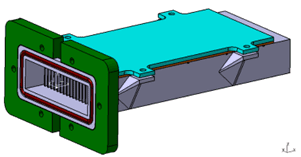

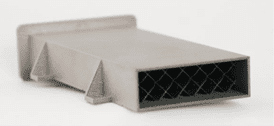

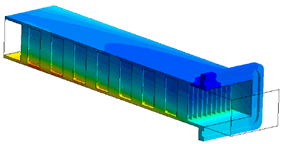

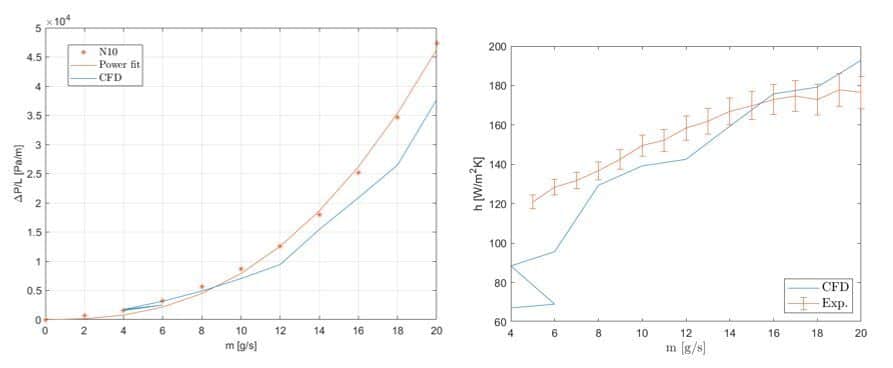

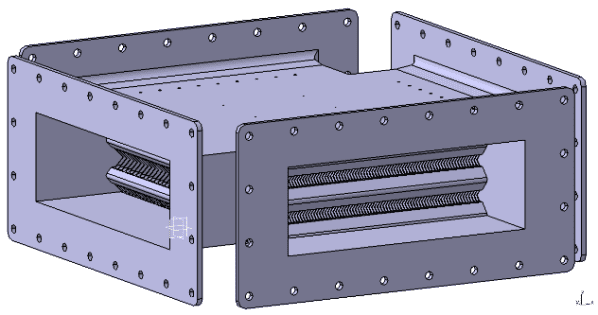

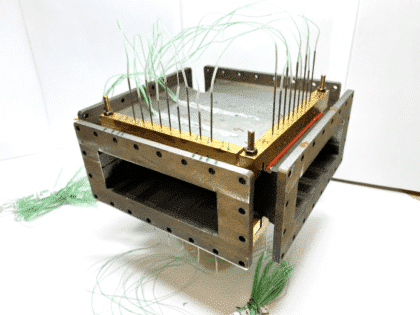

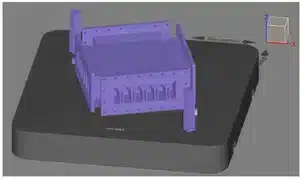

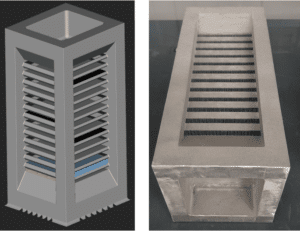

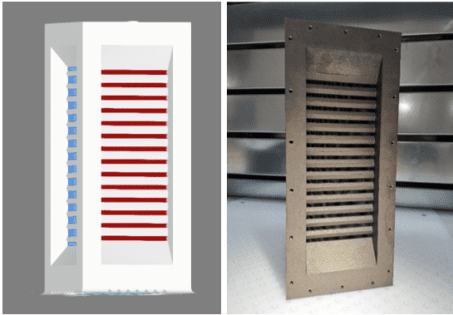

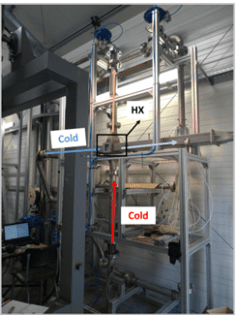

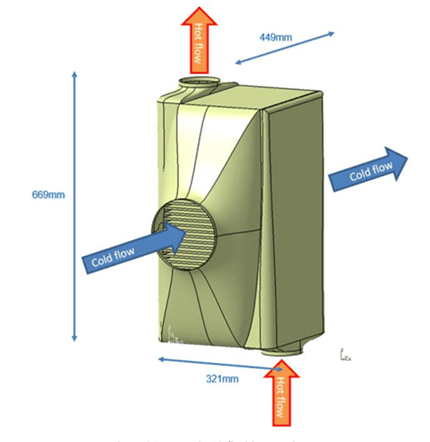

AddUp’s Autonomous Powder Module (APM) is a game-changer in the LPBF process, providing several advantages over traditional powder handling methods. The APM has several capabilities that make it an ideal powder handling solution for LPBF technology.

Ensure Quality

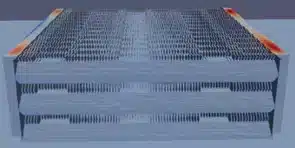

AddUp has designed the APM with quality in mind through Powder Reuse according to the ASTM F3456-22 standard which focuses on Traceability, Sieving, Powder Storage, and Used Powder criteria. The batch number traceability feature in the AddUp Manager Software allows for easy tracking and monitoring of the powder used, ensuring that the quality of the powder is maintained. The APM automatically sieves and regenerates the powder, ensuring that the powder is of the required quality, and reducing the need for manual intervention.

Maintain Process Control

The APM enables powder filling during production, which eliminates the need for operators to stop production to add powder, reducing downtime and increasing productivity. The APM fluidizes the powder, making it less cohesive, which improves the flowability of the powder during the LPBF process, ensuring that the powder is evenly distributed. The APM’s loss of powder traceability feature ensures that the powder is always tracked, minimizing the risk of loss or misplacement.

Increase Safety

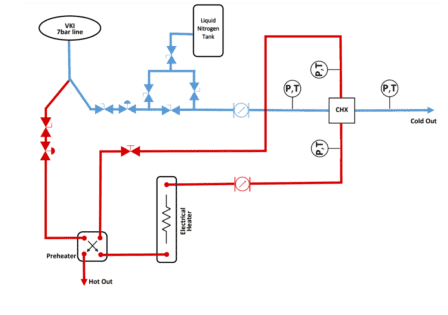

Complete inerting of the APM for powder storage, conveying, and handling with the use of a glove box during the loading and unloading of the powder, ensures that the powder is not exposed to the environment or to operators. The APM’s powder sample device allows for easy sampling of the powder at any time through the glove box, minimizing the risk of exposure to reactive powders. The APM’s automatic cycles for circuit purge and emptying ensure that the powder handling system is always clean, which also reduces the risk of contamination and exposure.

Minimize Cost

The APM’s powder handling system allows for one-time filling, minimizing powder waste and ensuring that the powder is used efficiently. The APM’s closed-loop system ensures that excess powder is automatically recovered during production and regeneration, minimizing powder waste, and reducing costs of powder inventory. Additional cost savings are also possible through the elimination of the tracking powder quantities for builds in progress. The APM’s vacuum system eliminates the need for a separate device for vacuuming at the end of the production, reducing costs and increasing efficiency. The APM’s stocking coefficient of 1.4 ensures that the powder is stored efficiently, reducing storage space requirements and costs.

Overall, the APM provides a streamlined and efficient powder handling solution, improving the quality, cost-effectiveness, safety, and productivity of LPBF technology.