A Complete Toolbox for Industrial AM

AddUp’s service team covers every angle of metal additive manufacturing. We listen first, then deliver what you need: training, consulting, digital solutions, machine maintenance, system upgrades and more all on your terms.

START

Get your team up to speed with targeted training, consulting, and application development. Build a practical understanding of additive manufacturing from the ground up.

LAUNCH

Ready to move into production? We help design your workshop, train your operators, and set up monitoring and quality systems to match your goals.

SCALE

Keep your operations running at their best. From onboarding new staff to fine-tuning processes and upgrading equipment, AddUp support adapts as your needs grow.

01 ADDUP HELPS YOU DEVELOP YOUR ADDITIVE MANUFACTURING EXPERTISE

Build Real Additive Manufacturing Know-How

- The basics of additive manufacturing

- Advanced training in metal additive manufacturing

- Understand L-PBF technology

- Understand DED technology

- Workshop for competency analysis

- Design for L-PBF Additive Manufacturing

Evaluate your additive manufacturing readiness

- On site visit by an AM expert

- Survey & Interview

- Immersion at AddUp site

- Workshop for competency analysis

Identify your use case and create a business model

- AM basics & key selection criteria

- Cost analysis

- Parts eligibility & business case workshop

- CO2 impact calculation

Co-design your applications and optimize your parts

- Part design, material & adaptation

- Topological optimization and simulation

- Integrate post-production operations

- Support strategy

- Distortion Simulation

- Preparation (layout, parts sorting & melting strategies)

- ROI and business model

Support services for the qualification of your applications

- Assess your procedure & impact analysis

- Workshop to define your action plan

- Support to collect data & information

- Workshop to build dataset

- Co-writing certification documents

- Support along the certification process

02 ADDUP HELPS YOU LAUNCH YOUR INDUSTRIAL CAPACITY

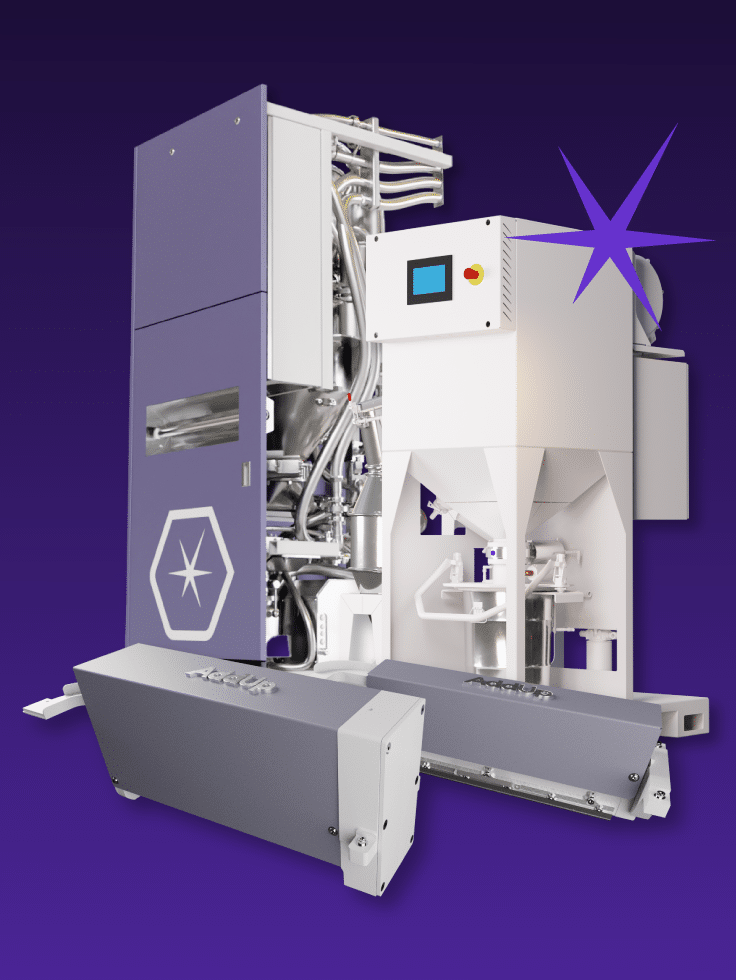

Install a FormUp as your metal additive machine

- HSE management for AM activities

- Manufacturing strategies

- Machine operation and level 1 maintenance

- Launch your first productions

- AddUp Manager and MyAddUp training

- Light preventive maintenance contract

Install your FormUp in an existing fleet

- HSE management for AM activities

- Manufacturing strategies

- Machine operation and level 1 maintenance

- AddUp Manager and MyAddUp training

- AddUp Dashboards installation and training

- Preventive maintenance contract

Highly productive use of your machine

- HSE management for AM activities

- Manufacturing strategies

- Machine operation and level 1 maintenance

- Autonomy ramp-up

- Define your future AM workshop

- Custom process parameters for known alloys

- AddUp Manager and MyAddUp training

- AddUp Dashboards installation and training

- Recoating and Melting Monitoring installation and training

- Preventive and curative maintenance contracts

Define your future additive manufacturing workshop

- Design

- Supply

- Installation

- Commissioning

- Knowledge transfer

Workshop as a service

- Choose the machine and its configuration

- Design or rent an appropriate workshop

- Supply powder

- Support with trained operators and experts

- Operation and Service

- Monitoring and Optimization

03 ADDUP IS YOUR PARTNER IN GROWING YOUR BUSINESS AND REACHING HIGH PRODUCTIVITY

Onboard new staff

- Tailor-made training program including:

- The basics of AM

- Manufacturing strategies

- Machine operation

- AddUp monitoring solutions (if present)

- Position-related knowledge (maintenance, process expertise…)

Optimize your production

- Basics on process parameters management

- Machine operation training — level 2

- Custom process parameters for known alloys

- Powder supplier qualification

- Post Treatment & machining Consulting

Develop level-2 in-house maintenance

- Year-to-year decreasing maintenance contract

- Maintenance training – level 2

- Tooling kits

- Power measurement checks kits

- Calibration kit

Support as your business grows by upgrading

equipment or switching material

- Support for impact analysis of the upgraded element until the equipment is requalified

- Support for material switch or new material development

- Support for machine relocation and validation

Your Uptime,

Our Priority

Focus on parts, not problems. Our support team is the single point of contact for keeping your production on track. Whether you need rapid troubleshooting, spare parts, or expert intervention, we deliver.

Same day shipping turnaround for in stock parts

Average response time to customers

Average time to have a technician on-site for resolution

“AddUp has demonstrated a set of capabilities that enable us to address unique design and application challenges faced by our growing base of aerospace, space, and defense customers.”

Greg Morris

“Our team has just returned fully delighted with this training. Everything contributed to a great success: the content, the quality of the trainers, the working environment.”

Thomas de Lesquen

“AddUp group has enabled our complex designs to become a reality using metal Additive Manufacturing, a state-of-the-art process. This will change the way we create and customize a motorcycle. Our creativity is now limitless, which was impossible with traditional metal manufacturing processes.”

Simon Dabadie

TRAINING SOLUTIONS

AddUp offers a comprehensive catalog of training modules dedicated to metal additive manufacturing. We provide skills development programs adapted to every job position and all maturity levels, for industrial and academic sectors.

From early adopter to expert level

Our training modules are built to meet the needs of all company profiles. AddUp can help your employees understand metal 3D printing technologies, integrate HSE risks, acquire skills in design for additive manufacturing (DFAM), or become experts in fields such as process parameters management or maintenance.

Training CatalogDeploy the culture of metal AM in your company

AddUp has developed a series of e-learning courses, which are being used by several industrial companies, but also schools and universities. With 12+ hours of training, more than 100 videos and 200 exercises, AddUp Academy Online provides all the knowledge needed to be able to start a project with metal additive manufacturing.

AddUp AcademyTraining programs for AddUp machine users

AddUp machine users benefit from a complete training program, including HSE risks management, manufacturing strategies and machine operation. The skills development continues after the installation of the machine, with expert trainings for preventative maintenance operations or process parameters management, and specific training programs for the onboarding of a new employee to your team.

Training CatalogCONSULTING SERVICES

Our team of expert consultants assists you in every step of your project. They can help in the early phases, when you need to identify and create your first use case, but also in the design and industrialization phases, up to the qualification of your application and the optimization of your production capacity.

Request Consulting ServicesIntegrate Metal AM

AddUp’s consultants help you anticipate and experiment the required changes to integrate metal additive manufacturing in your company, with audits, interviews and workshops with key members of your team.

Business Model Creation

To make sure you choose the best application, AddUp provides parts screening services and support for cost calculations, CO2 impact and return on investment.

Part Optimization

Our team of experts in Design for Additive Manufacturing (DFAM) can “co-design” your application to ensure the feasibility of the parts. They can handle all activities related to design. This includes: simulation, topological optimization, support strategy, production simulation, and post-printing operation.

Application Qualification

If your application must be certified by qualification authorities, AddUp supports you along the certification process with methods, templates and expertise.

Future AM Workshops

We are experienced in designing AM workshops, both internally and for our customers. We can support you in the creation of a workshop that suits your needs in terms of capacity, flow management, automation, and safety management.

Production Optimization

Not only will our team get you operational with your AddUp machine, but we will guide you to optimize your process and maximize your production. This includes process parameter development, manufacturing strategies and workflow.

DIGITAL SOLUTIONS

Our digital solutions drive better traceability, higher quality, and faster troubleshooting. Upgrade your operation with software and hardware built to industrial standards. Enable traceability of your production, reduce the probability of defects in your parts, and assess the conformity of the printing process.

Our production supervision solution is a powerful application on which you can display synthetic or detailed information about your machines. A wide range of predefined dashboards will help you follow production indicators, manage alerts, compare several productions, optimize maintenance intervals, or operate diagnostic.

Our machines can be equipped with an advanced technology which analyzes the quality of the powder bed and launches automatically a new powder spreading cycle if necessary. Thanks to a closed-loop algorithm, the decision is taken is less than one second negating the risk of having defects in the build and limiting impact on productivity.

With AddUp’s unique Melting monitoring technology, essential parameters of the melt pool (position, power, thermal emission) are monitored in real-time or after the production. The large amount of data collected during printing will make it possible to detect any difference between the produced part and the referenced one, improving the confidence in your process and reducing the number of non-conforming parts.

MAINTENANCE CONTRACTS

We provide the gold standard of maintenance service for all our customers, complimented by:

MAINTENANCE CONTRACTS

We provide the gold standard of maintenance service for all our customers, complimented by:

MACHINES UPGRADES

Your machines can be upgraded at any time for better productivity, quality or safety

Our FormUp 350 range of machines is based on an open architecture, allowing upgrades to take advantage of new technologies and ensuring that your machine is never obsolete.

MACHINES UPGRADES

Your machines can be upgraded at any time for better productivity, quality or safety

Our FormUp 350 range of machines is based on an open architecture, allowing upgrades to take advantage of new technologies and ensuring that your machine is never obsolete.

Contact Our Service Team

Don’t hesitate to reach out to speak with one of our Service Technicians.

Already an AddUp customer? Visit our customer portal.