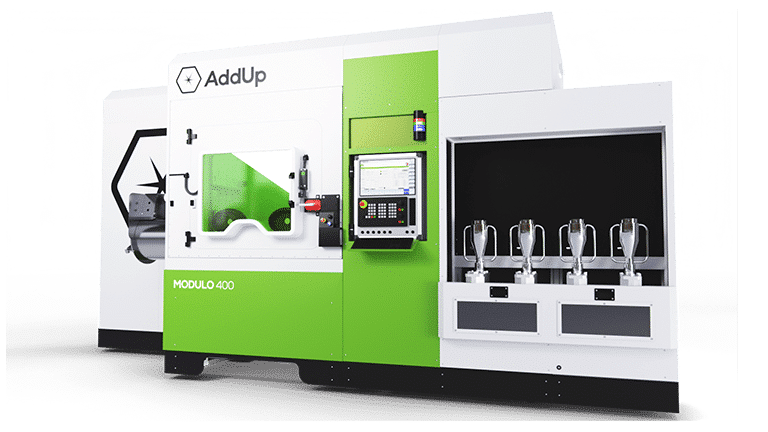

MODULO 400

The Modulo 400 is a compact and integrated ded machine. It is designed for industrial production and equipped with a standard 10Vx nozzle powered by a 500W laser. An optional second 24Vx nozzle powered by a 2kW laser is available.

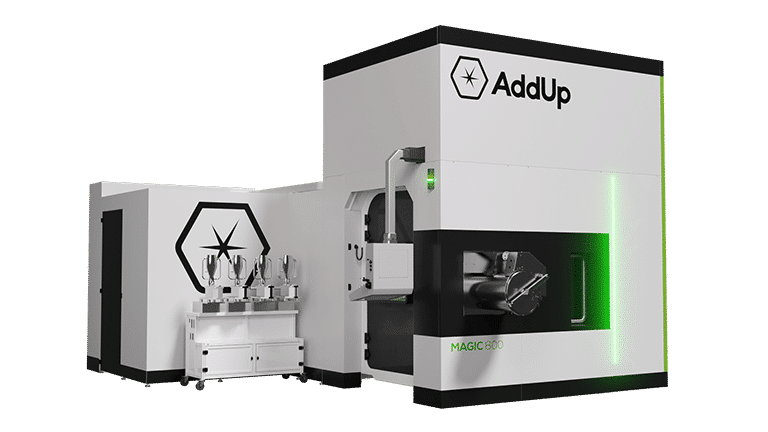

MAGIC 800

The Magic 800 is a large-format machine, suitable for the manufacture or repair of large parts. It is equipped with a standard 24Vx nozzle powered by a 2kW laser. An optional second 10Vx nozzle powered by a 500W laser is available.

As standard with two deposition nozzles: a nozzle equipped with a 10Vx laser, for areas of parts that require precision, and a nozzle equipped with a 24Vx laser for areas of parts that can be produced with high productivity.

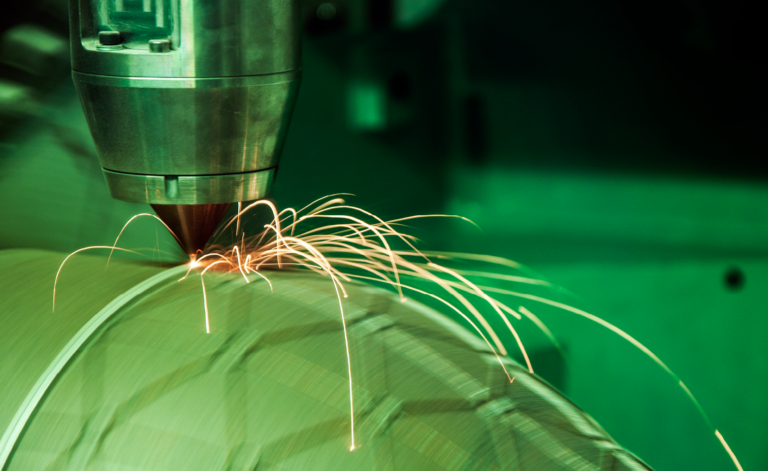

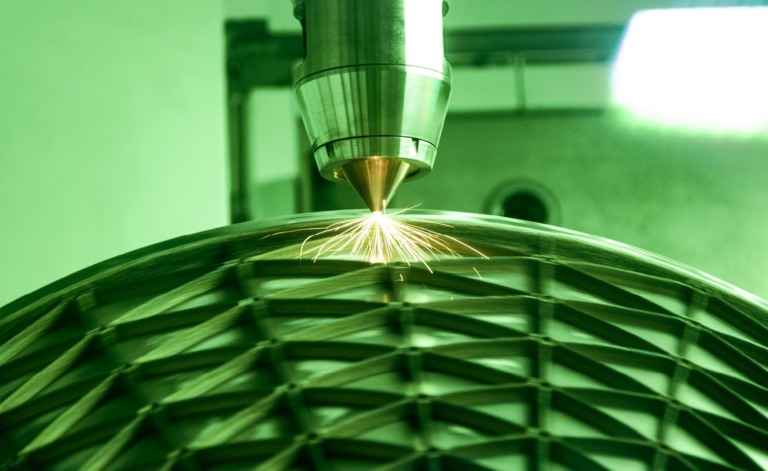

DED TECHNOLOGY

Directed Energy Deposition (DED) technology is a process of bringing metal powder into a melt pool created by a laser. Parts are created by an overlay of weld beads.

The advanced technology of our DED machines is suitable for the manufacture of large parts.

- Repair of worn or deteriorated parts

- Addition of features (modifying the geometry of an existing part)

- Metal coating on existing parts (modification of part properties)

- Creation of new materials from multiple metals

SMART FEATURES INTEGRATION

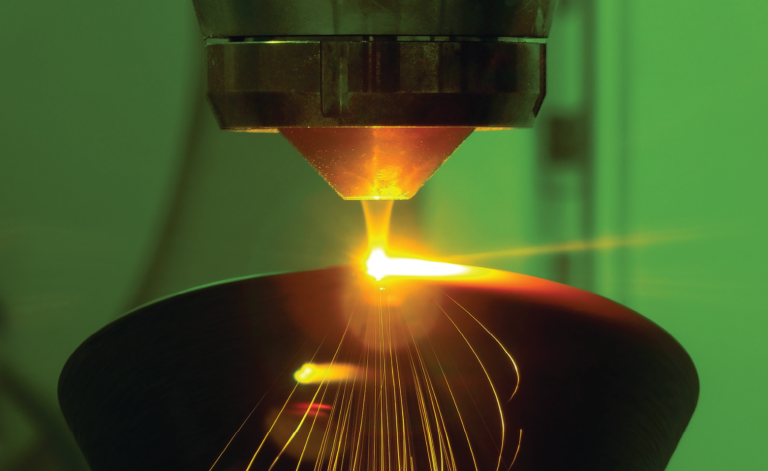

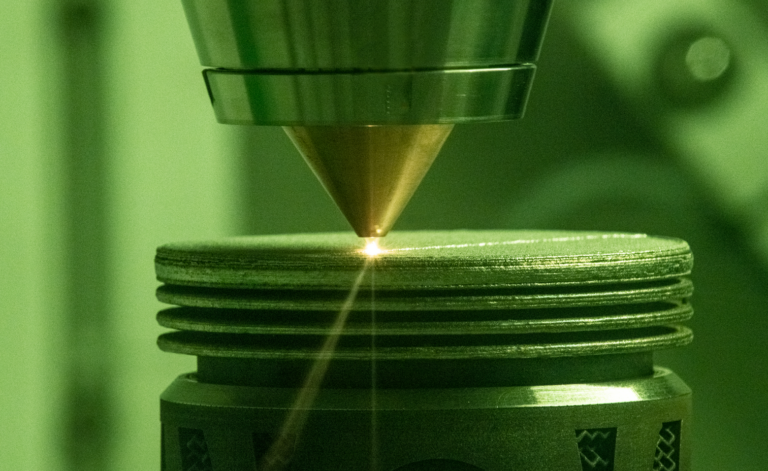

IN-HOUSE DESIGNED NOZZLES

Our in-house designed nozzles achieve a smoother finish, with better meltpool control, and less overspray for minimal post processing. Two different nozzles can be mounted on our DED machines: the 10VX, which is the standard one and perfect for working on fine parts thanks to its deposition width from 0.8 to 1.2 mm, and the 24VX which increases width up to 2.2mm.

INERT CHAMBER

Another major advantage of DED AddUp machines is their inert chamber, which enables them to work with reactive powders. This feature makes our DED machines one of the few on the market capable of producing titanium parts

Enter The Smart Era in Metal Manufacturing

Today’s metal 3D printers make parts that can’t be made by traditional manufacturing methods. Metal Additive Manufacturing is the way of the future and AddUp is leading the way.