The results of the $1.5M research contract “Development of Manufacturing, Heat Treatment, and Surface Finishing Guidelines to Yield Ready-to-Use IN- 718 Additive Manufacturing Components” are complete and AddUp achieves the #1 ranking among participants in a High Cycle Fatigue (HCF) study. The contract was initiated through the United States Air Force (USAF) and the Small Business Innovation Research (SBIR) program and was led by REM Surface Engineering (REM).

Advancing Legacy Armament Systems with IN-718 Additive Manufacturing

Aimed to harness the potential of laser powder bed fusion (L-PBF) and surface finishing technologies to produce IN-718 components for legacy armament systems, the study researched the impact of various heat treatment and printing parameter combinations in association with REM’s surface finishing technology. The goal was to learn what effect each combination would have on a component’s mechanical properties such as tensile strength and fatigue life.

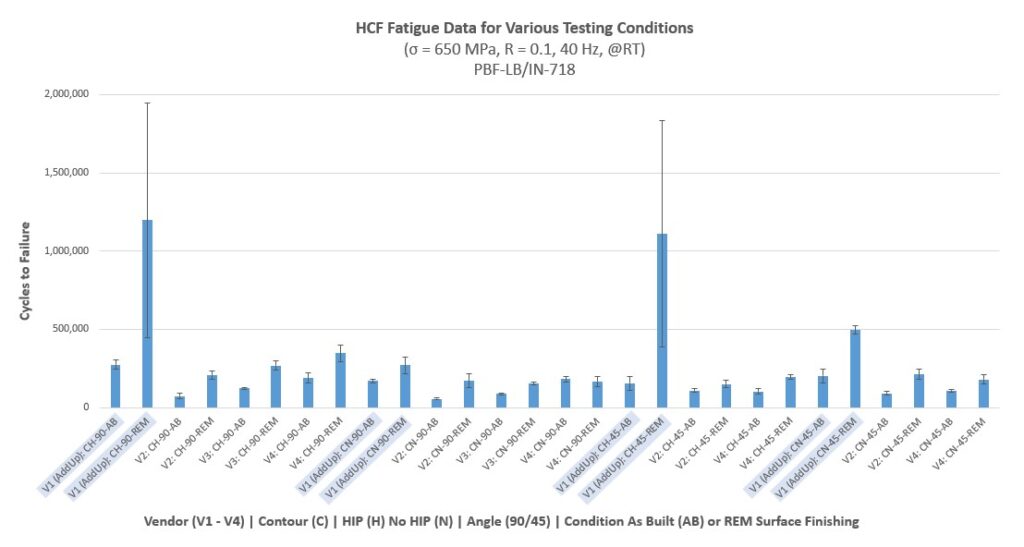

This blind study had participation from four major metal additive manufacturing OEMs/service bureaus and included a variety of critical testing conditions to determine fatigue performance in AM components. These conditions included Hot Isostatic Pressing (HIP) versus non-HIP treatments, contour versus non-contour melting strategies, and angled printing at multiple angles including 0, 45 and 90 degrees. Among the anonymous OEM participants, AddUp identifies themselves as vendor #1 (V1) and outperforms competitors, especially when parts produced on the FormUp 350 were combined with REM’s surface finishing technology, the Extreme ISF® Process, enhancing material properties for corrosion and fatigue resistance.

The robust combination of AddUp’s PBF technology and REM’s surface finishing process underscores new opportunities for USAF components. AddUp’s fine powder and roller recoater system on the FormUp 350 has become known in the market for its best-in-class surface finish. Surface finish plays an important role in fatigue strength and REM’s novel surface finishing solution further strengthened these properties, reducing material degradation and maximizing performance and reliability.

“The results from this research program are of great value to the DOD and the additive industry overall,” stated Dr. Agustin Diaz, Advanced Manufacturing and Innovation Manager at REM Surface Engineering. “The fatigue study shows that the combination of AddUp’s PBF-LB technology with REM’s surface finishing process generated the highest fatigue resistance, providing valuable data for potential aerospace and defense component applications.”

Fatigue Resistance: A Critical Component in IN-718 Performance

Fatigue resistance is essential in IN-718 applications, particularly in demanding aerospace and defense environments where structural integrity and reliability are crucial. The results from this study emphasize how fine-tuned AM parameters combined with advanced finishing technologies can reduce component downtime and cost, ensuring mission-critical operations proceed with enhanced performance.

About REM Surface Engineering:

REM Surface Engineering is a global provider of surface engineering solutions to NASA, the DOD, and commercial industries for both traditional/subtractively manufactured components as well as additively manufactured components. REM is a US-based small business with sister companies in the UK and Germany.

REM’s Extreme ISF® Process, is a suite of subtractive, isotropic superfinishing processes tailored to the metal additive manufacturing industry. The technology is capable of reducing the extreme surface roughness associated with metal additive manufacturing while removing or remediating surface and near surface defects such as voids and v-notch failure points and/or providing a mirror-like aesthetic appearance. The process is applicable to external surfaces as well as internal, none-line-of-sight surfaces. Applicable alloys include Aluminum, Copper, Stainless Steel, and Titanium alloys as well as Nickel-Based Superalloys, and Refractory Alloys. REM offers the Extreme ISF Process as an outsourced solution or as a complete technology installation.

REM’s ISF Technologies have been used to enhance the performance of parts in many industries, providing benefits such as reduced friction and wear, improved bending fatigue and improved corrosion resistance. All REM locations operate under an ISO 9001:2015 and AS9100:2016 Rev. D certified Quality Management System. For more information, visit www.remchem.com.