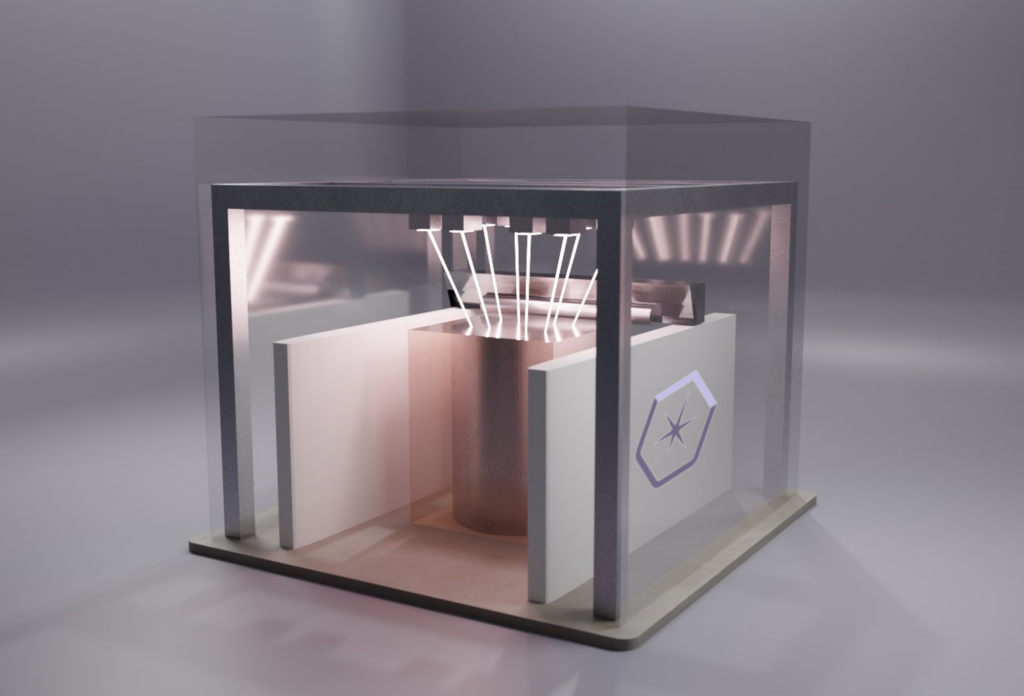

AddUp is excited to introduce an innovative development poised to redefine the future of metal additive manufacturing. The project, named “MASSIF” (Metal Additive System, Sustainable, Industrial, Eco-Friendly) supports a broader strategy to drive the next wave of industrial and technological innovation around large-format metal AM Powder Bed Fusion (PBF) additive manufacturing (up to 1.5m x 1.5m x 2m). This project is designed to boost productivity, reduce costs, and meet evolving sustainability goals, offering unparalleled capabilities for industrial applications. The first PBF machine developed around these concepts features a remarkable print volume of 750mm x 750mm x 1m high.

Built on the Proven Foundation of FormUp 350

The new machine will leverage the robust foundation of AddUp’s FormUp 350, a highly reliable and precise platform designed for demanding industrial environments. With unmatched throughput and accuracy, the FormUp 350 has proven its capability in serial production, currently being used by customers across the world to deliver thousands of critical components such as medical implants, satellite and aerospace parts. Trusted by customers across aerospace, medical, and other high-precision industries, it stands as a benchmark for quality and performance in metal additive manufacturing.

A Game-Changer for Additive Manufacturing

Additive manufacturing is known for offering significant advantages over traditional methods of manufacturing, enabling greater design flexibility, faster production times and an eco-friendlier approach. This new machine takes these benefits to a new level, with key advancements that deliver unprecedented value to customers:

- Unmatched Productivity: The MASSIF machine is set to increase productivity by 300%, drastically reducing part costs by 50-70%.

- Massive Build Volume: With the capability to manufacture parts 12 times larger than current AddUp machines, the MASSIF machine pushes the boundaries of scale for metal additive manufacturing.

- Minimized Waste: With less than 10% powder waste, this machine guarantees a more sustainable production process.

- Superior Quality: The MASSIF machine ensures top-quality parts straight off the printer, utilizing AddUp’s proprietary technology to deliver best-in-class surface finishes that minimize or eliminate the need for costly and time-consuming post-processing. Additionally, its robust in-process monitoring instills confidence that parts are printed correctly from the start, reducing the need for expensive quality assurance testing afterward.

- Eco-Friendly Focus: Emphasizing a forward-thinking, responsible approach to manufacturing, the MASSIF machine uses decarbonated energy, aligning with global sustainability goals.

Driving the Future of Industrial and Technological Innovation

The machine will be developed in collaboration with renowned companies Cailabs, CETIM, Dassault Systèmes, ISP Systems, and Vistory and has been selected as the winner of the prestigious #France2030 “Robots and Intelligent Machines of Excellence” program. The project, named “MASSIF” (Metal Additive System, Sustainable, Industrial, Eco-Friendly) supports a broader strategy to drive the next wave of industrial and technological innovation. By 2030, the “Robots and Intelligent Machines of Excellence” program envisions a highly automated and intelligent industrial ecosystem, contributing to economic growth and sustainability.

“It was the association of the best experts, each in their field, that allowed us to launch the MASSIF project. This technological leadership in large-scale metal 3D printing will enable us to meet the challenges of energy transition and productivity for aeronautics, defense and space players, always in a co-design approach by AddUp with its clients.” explains AddUp CEO, Julien Marcilly.

The MASSIF project is a testament to innovation and collaboration. Under the leadership of AddUp, the consortium brings together the unique expertise of each partner to create a machine that is not only larger but also more productive, efficient, and eco-friendly than anything currently available on the market.

- AddUp, the consortium leader, is designing the machine and building a prototype that integrates the technological building blocks of the process and production quality monitoring solutions.

- Cailabs develops laser beam shaping solutions to increase printing speed and thus machine productivity.

- ISP Systems develops a dynamic beam shaping solution to improve LASER beam focusing quality.

- Dassault Systèmes, which with the 3DEXPERIENCE® platform enables real data to be used to create virtual models that simulate products, processes and factory operations in the virtual twin experience, develops a data enhancement solution aimed at the efficient manufacture of certified critical parts

- Vistory, is developing a solution that guarantees the confidentiality and integrity of manufacturing data, protecting the creator’s industrial property and ensuring the traceability of operations.

- CETIM is contributing to the technological development of the prototype by carrying out tests on its own facilities, then integrating the final machine in its new Printing Bourges center, in order to validate the manufacturing parameters for different materials and produce the first demonstration parts for the various target markets.

Project Timeline

The MASSIF project is underway, with the process of prototyping and initial production already in motion. The first machine is anticipated to be installed at CETIM’s Printing Bourges center, where it will undergo further validation. As the project progresses, MASSIF is poised to meet the industry’s increasing demand for productivity, cost-efficiency, and high-quality parts, all while fostering a more sustainable future in manufacturing.