Armadillo Additive, an ISO 13485-certified contract manufacturer serving the medical industry, is expanding its metal 3D printing capacity with two additional AddUp FormUp 350 Laser Powder Bed Fusion (LPBF) machines. This investment brings Armadillo Additive’s FormUp 350 total to three. Now, they are adding 17-4 Stainless Steel and Grade 1 Titanium to complement their existing offering of Grade 23 Titanium.

“By adding two more FormUp 350 machines to our facility, our team is uniquely positioned to offer unmatched throughput and material versatility to our customers,” said Noah Smith, Director of Operations at Armadillo Additive. “Our first FormUp 350 has proven its reliability, surface finish quality, and overall throughput. We’re excited to continue our growth alongside AddUp and remain a trusted partner for our customers.”

Armadillo Additive selected AddUp’s FormUp 350 machines based on their reliability, production efficiency, and strong safety features. The autonomous powder module and advanced filtration system contribute to a safer working environment. The FormUp 350 also delivers an unrivaled, superior quality surface finish straight from the printer, reducing the need for extensive post-processing. And the machine’s large build volume and quad-laser configuration allow for increased productivity and flexibility in manufacturing. These features combined with AddUp’s robust software suite ensures consistency and confidence in production that Armadillo Additive expects from their machines.

Expanding Material Capabilities for Medical and Beyond

Armadillo Additive is an ISO 13485:2016 – certified contract manufacturer known for its comprehensive end-to-end solutions for medical OEMs. Their services now include metal 3D printing via laser powder bed fusion, laser marking, heat treatment, media blasting, and passivation. Additionally, they assist customers with necessary documentation for FDA submissions.

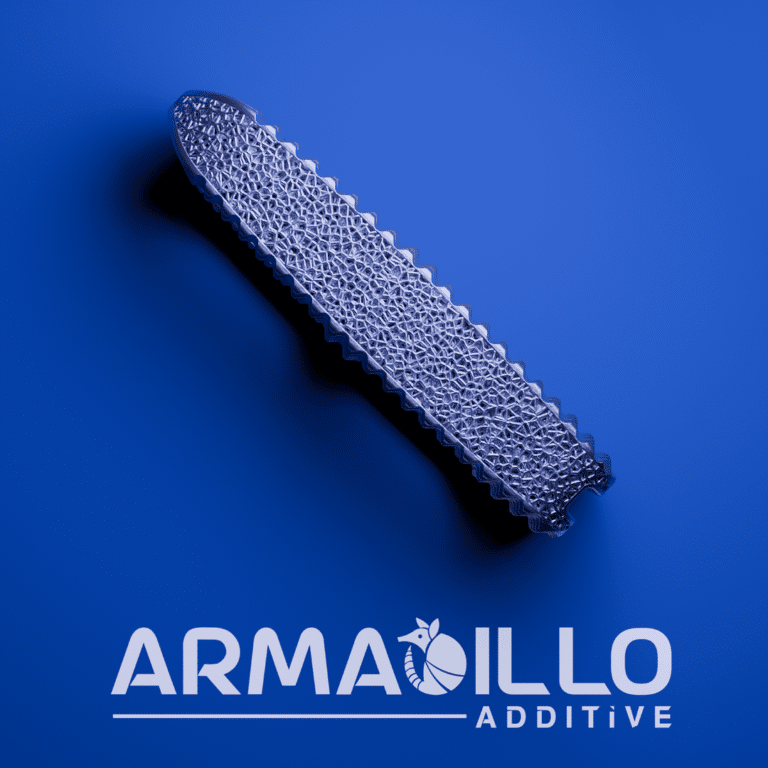

Their existing FormUp 350 machine has been successfully running Ti6Al4V ELI (Grade 23) for medical implant production. The addition of two new FormUp 350 machines will enable Armadillo Additive to expand beyond this single material, incorporating 17-4PH stainless steel for surgical instrumentation and Cp Ti (Titanium), which offers unique properties suited for specialized medical applications. This expansion allows Armadillo to support a broader range of applications, including research and development, implants, and intricate lattice structures that optimize strength and material efficiency.

“With these new capabilities, we are well-positioned to support OEMs requiring high-value, high-volume production,” Smith added. “Our expertise in orthopedic applications, along with our in-house services like laser marking, heat treatment, and bead blasting, ensures we deliver complete solutions that meet the rigorous demands of medical engineering.”

While the company’s primary focus remains on medical applications, Armadillo Additive also plans to leverage its expanded material capabilities to serve broader industries beyond healthcare.

“At AddUp, we are committed to supporting our customers as they expand into new markets and scale their businesses,” said Nick Estock, Deputy CEO at AddUp Inc. “The addition of these two FormUp 350 machines will position Armadillo Additive to offer a truly complete solution to their customers, reinforcing their leadership in the medical manufacturing space while opening doors to new opportunities.”

The two new FormUp 350 machines are expected to be delivered in the Spring of 2025. Armadillo Additive and AddUp will be at the American Academy of Orthopaedic Surgeons (AAOS) conference in San Diego (March 11-14, 2025) showcasing their latest developments printed on the FormUp 350. Stop by their booths to learn more about their capabilities.

About Armadillo Additive:

Armadillo Additive is a US-based contract manufacturer for devices in Granbury, Texas just outside of the DFW metroplex. They offer additive manufacturing services to OEMs looking to take advantage of Grade 23 Titanium, CP Ti, and 17-4 Stainless Steel.

Armadillo Additive’s printing services leverage three of the next generation 3D printer from AddUp, the FormUp 350. With the printer’s industry-leading build volume, quad lasers, and roller recoater, Armadillo Additive offers best-in-class throughput without sacrificing quality.

While 3D printing is their primary focus, Armadillo Additive’s in-house services and external partnerships create an end-to-end solution. From laser marking and passivation to heat treating and inspection, Armadillo Additive is ready to bring designs to life.

For more, visit: https://www.armadilloadditive.com