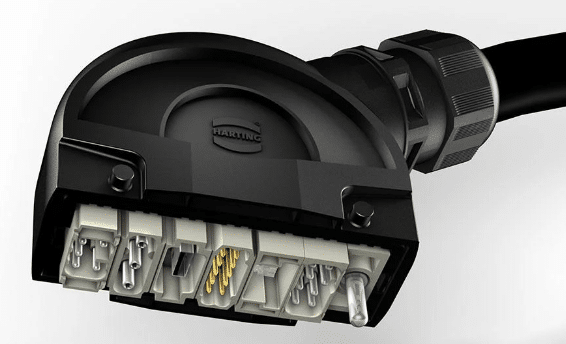

High-volume plastic components place strict demands on cooling performance, tool stability, and cycle time efficiency. For the Han-Eco plug, one of HARTING’s most widely used industrial connectors, thick wall sections and annual volumes exceeding one million units amplify these challenges. Even small improvements in cooling performance translate directly into significant productivity gains.

To explore these gains, HARTING Applied Technologies partnered with AddUp to evaluate whether conformal cooling produced through additive manufacturing could outperform traditional tooling methods. The project focused on reducing residual cooling time, eliminating thermal hotspots, and validating the use of corrosion-resistant AM tool steels for future series production. Early simulation work and prototype tooling confirmed that AM-enabled cooling could deliver measurable and repeatable benefits at industrial scale.

From Hotspots to High Output:

Accelerating Tooling Efficiency with Additive Cooling

MATERIAL

Printdur HCT (1.2083 / PM420)

INDUSTRY

Tooling and Mold Making

CHALLENGE

Reduce cycle time and eliminate thermal hotspots in a thick-walled plastic plug for annual production volumes over one million units, by replacing conventional mold cooling channels with an additively manufactured conformal-cooling solution.

KEY BENEFITS

- More than 25 percent reduction in cooling time

- Uniform tool temperature without hotspots

- Higher throughput and more stable production

- Lower scrap rates and improved part quality

- Scalable 3D cooling design for the full Han-Eco tool family

Shorten Cycle Times

Increased Production Rate

Scalable

The Customer

The HARTING Technology Group is a leading global supplier of industrial connection technology, supported by a high degree of in-house vertical integration. This includes a modern mold-making department that is continually exploring new ways to enhance HARTING products. In recent years, the company has gained valuable experience with advanced cooling concepts.

Building on this expertise, HARTING is now evaluating the feasibility of additive manufacturing as a standard process for selected series components.

Injection molding has been especially promising in these studies, as the use of conformal cooling can significantly improve part quality and increase tool productivity.

The Challenge

HARTING produces large volumes of plastic components for sectors such as energy, transportation, and mechanical engineering. With this level of demand, even small reductions in cycle time have a significant impact on overall production cost, making cooling performance a key driver of efficiency across the product family.

One example is the Han-Eco plug, one of the most important products in HARTING’s portfolio, and features relatively thick wall sections designed to meet strict functional requirements. These characteristics create a cooling challenge, particularly when annual volumes exceed one million units. Adopting an additive manufacturing approach to the cooling design enabled focus on several key objectives:

- Increasing production rates for plastic components

- Shortening cycle times

- Reducing required machine space

- Reducing overall manufacturing time

- Evaluating new corrosion-resistant AM tool steels

The Solution

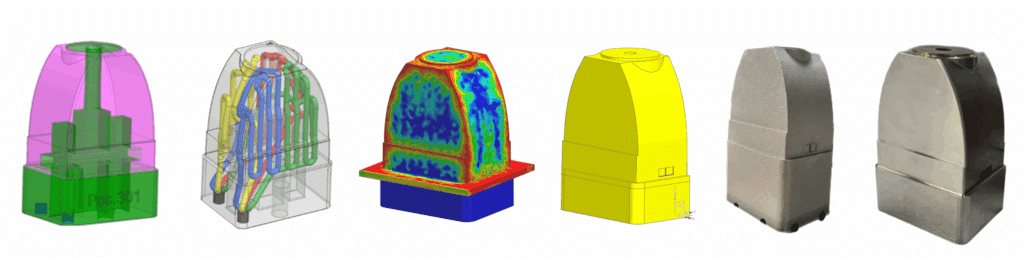

The first step was to analyze and verify the potential for improvement using simulation combined with a conformal cooling concept. This early investigation is important for the Han-Eco product family because any lessons learned from additive manufacturing can be transferred to additional tools within the series.

Using the Siemens NX simulation environment, these studies could be run quickly during the early stages of tool development. Once the potential of additive manufacturing was confirmed, the cooling strategy was refined. This stage focused on designing a fully three-dimensional conformal cooling system that follows the contours of the cavities and surrounding tool surfaces. The cooling channels were optimized for flow performance through close collaboration between AddUp and HARTING. The final system uses a four-path parallel cooling circuit that ensures balanced flow and consistent thermal behavior.

Unlike conventional cooling channels that must be drilled or milled in straight lines, conformal cooling allows channels to follow the geometry of the mold. This removes heat exactly where it is generated and results in shorter cooling times, improved thermal uniformity, and better component quality.

This approach enables:

- Shorter cycle times

- More uniform temperature distribution throughout the mold

- Reduced warping and improved dimensional stability

- Stable and reliable processing at high output levels

Traditional manufacturing methods such as drilling or milling quickly reach their limits when handling complex geometry. To overcome this, toolmakers often join mold halves through vacuum brazing to create more intricate cooling paths. Although functional, this approach introduces several drawbacks such as restricted channel geometry, the inability to create true 3D contours, increased risk of leakage, lower thermal conductivity, and higher effort during repair.

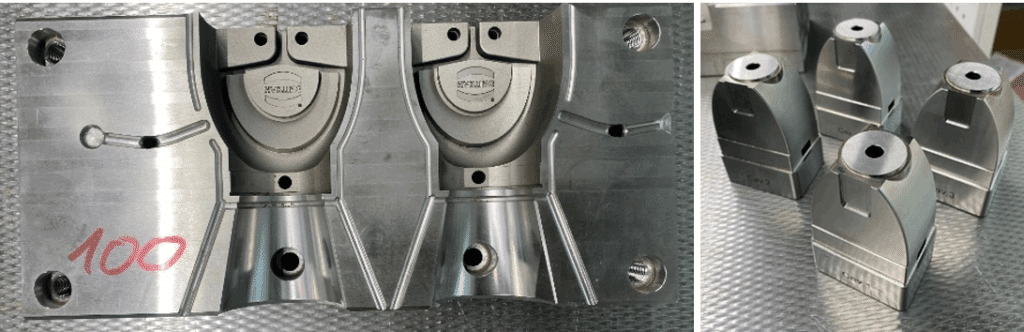

With additive L-PBF technology on the AddUp FormUp 350, the entire insert can be produced as a single piece with fully integrated cooling channels. This capability reduces cycle times, decreases scrap rates, and significantly increases output per machine. These advantages are especially important for thick-walled components such as the Han-Eco connector.

Reduced Manufacturing Time: Inserts and Cores

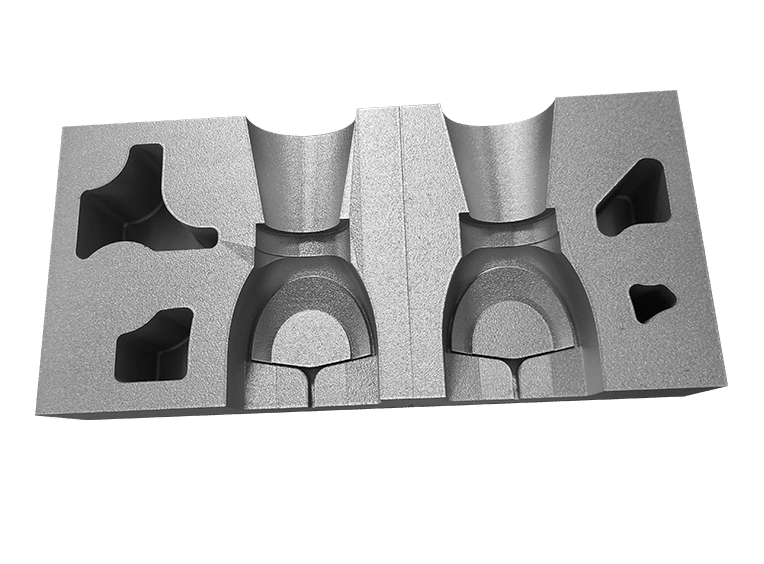

The new AM inserts (two AS and DS units) and AM cores (four units) were produced on the AddUp FormUp 350 using a four-laser configuration. The chosen material was a corrosion-resistant, high-strength tool steel based on 1.2083 / PM420, which is well suited for injection molding and supports high-gloss polished surfaces (class 1). After printing, the parts were deburred, heat treated, and separated from the build platform. Final machining was completed at HARTING to achieve the required tolerances and surface finish.

The Results

Thermal performance was evaluated by recording temperature patterns on molded parts using a thermal imaging camera. Measurements were taken on parts produced with the conventional tool and with the additively manufactured tool under the same operating conditions.

After 15 seconds of residual cooling time, the additively cooled tool showed hotspot temperatures that were approximately 10 °C lower than those observed with the conventional tool. The thermal profile of the AM tool at 15 seconds matched the profile of the conventional tool at 20 seconds, confirming a meaningful acceleration in heat removal.

These findings demonstrate several clear improvements:

- Residual cooling time reduced by more than 25 percent, from 20 seconds to 15 seconds

- More uniform temperature distribution across the molded part, with hotspot regions significantly reduced

- Improved thermal stability that supports consistent quality at high output levels

The collaboration between AddUp and HARTING confirms that conformal cooling produced through L-PBF can resolve the limitations of straight-line cooling channels. By integrating fully three-dimensional cooling paths inside a single-piece mold insert, the process improves throughput, increases tool reliability, and provides a scalable model for other Han-Eco series tools.